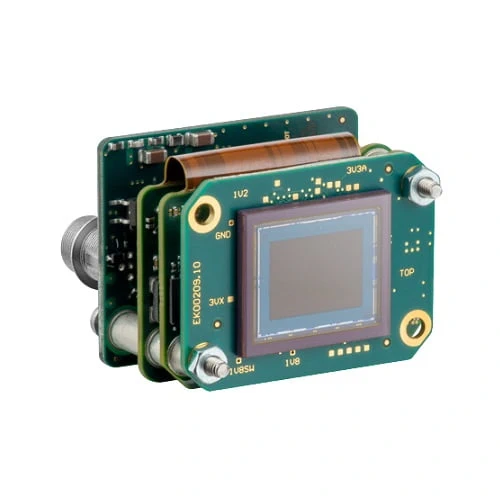

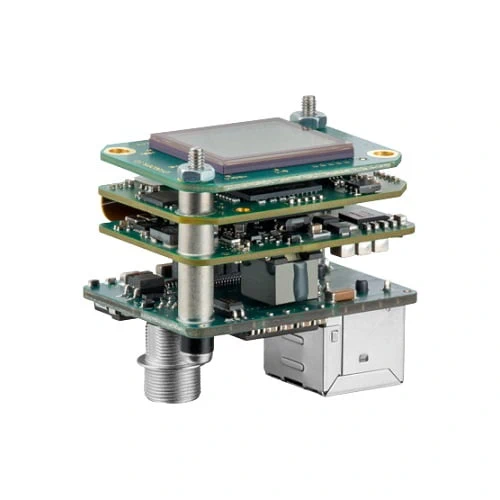

Key Features & Specifications – IDS UI-5292SE Rev.4.2: [Color: AB12268], [Mono: AB12269]

| Feature | Details | Benefit |

|---|---|---|

| Sensor Brand & Model | Sony IMX267LQR (Color) / IMX267LLR (Mono) | Proven industrial sensor delivering stable image quality and long-term availability |

| Sensor Type | CMOS, Global Shutter | Eliminates motion distortion for accurate imaging of fast-moving objects |

| Interface | GigE (RJ45) | Reliable long-distance data transmission and easy industrial network integration |

| Interface Speed | Up to 1 Gbps | Ensures consistent data flow for high-resolution image transfer |

| Resolution (H × V) | 4104 × 2174 pixels (8.92 MP) | Captures fine details across wide inspection areas |

| Optical Area (H × V) | 14.159 mm × 7.500 mm | Supports large field-of-view imaging with high detail density |

| Optical Format | 1″ (Diagonal 16.02 mm) | Compatible with high-quality industrial lenses |

| Pixel Size | 3.45 µm | Balanced sensitivity and resolution for demanding lighting conditions |

| Lens Mount | No mount (board-level / modular integration) | Enables flexible system and custom optical design |

| Image Memory | 128 MB | Supports reliable buffering during triggered or burst acquisition |

| Frame Rate @ Max. Resolution | Up to 12 fps | Suitable for controlled-speed inspection and monitoring tasks |

| Shutter | Global Shutter | Guarantees geometrically correct images of moving targets |

| Exposure Time | 0.047 ms to 1000 ms (up to 30 s long exposure) | Adapts to both high-speed capture and low-light environments |

| Trigger & Flash I/O | Hardware trigger, opto-isolated flash output, GPIO | Precise synchronization with external lighting and controllers |

| Power Supply | 12–24 V DC or Power over Ethernet (PoE) | Simplifies cabling and system power design |

| Software Tools | IDS peak software suite | Accelerates setup, configuration, and image processing |

| Environmental Tolerance | Operating 0 °C to 55 °C, non-condensing | Designed for stable operation in industrial environments |

| Housing Protection | Open industrial design | Ideal for protected enclosures and embedded systems |

| Size & Weight | 31.5 × 40.0 × 30.0 mm, approx. 38 g | Compact and lightweight for space-constrained installations |

| Special Imaging Modes | Line-scan mode, ROI, decimation | Enhances performance flexibility for specialized applications |

Download IDS UI-5292SE Rev.4.2 Color (AB12268) Datasheet

Download IDS UI-5292SE Rev.4.2 Mono (AB12269) Datasheet

Download IDS UI-5292SE Rev.4.2 Technical Drawing

The Applications

1. High-Speed Conveyor Inspection in Manufacturing

In automated production environments, parts often move continuously, making image distortion a major risk for inspection accuracy. A 9 MP global shutter sensor captures the entire image at once, ensuring that edges and shapes remain true even when objects move quickly across the field of view. The high resolution allows a single camera to monitor wide conveyors while still resolving small defects such as chips, scratches, or missing features. Precise hardware triggering aligns image capture with part position, while adjustable regions of interest reduce processing load. This results in stable, repeatable inspection without slowing production throughput.

2. Printed Circuit Board Inspection Systems

Electronic assemblies demand extremely sharp images to identify solder defects, misplaced components, or fine trace issues. With a global shutter sensor, boards moving under the camera are captured without skew or blur, preserving accurate geometry. The 9 MP resolution provides enough detail to inspect an entire board in one frame, reducing system complexity. Flexible exposure control supports consistent imaging under controlled lighting, while synchronized trigger and flash signals improve contrast and repeatability. These capabilities help inspection systems detect defects reliably while minimizing false rejections in high-volume electronics production.

3. Optical Measurement and Dimensional Verification

Non-contact measurement systems rely on consistent geometry and pixel accuracy to produce trustworthy results. A high-resolution global shutter sensor supports precise edge detection across large measurement areas, making it suitable for gauging, profiling, and dimensional verification. Because all pixels are exposed simultaneously, measurements remain accurate even when objects vibrate or move during capture. Exposure flexibility allows engineers to balance motion freezing and signal strength. Combined with deterministic triggering, the camera delivers repeatable data essential for quality control and traceable measurement processes in industrial metrology.

4. Vision-Guided Industrial Robotics

Robotic systems require reliable visual feedback to locate, align, and manipulate parts accurately. A global shutter sensor ensures distortion-free images even when robots or components are in motion, enabling precise position calculation. High pixel resolution improves localization accuracy, supporting tighter tolerances and more complex assemblies. Hardware I/O enables close synchronization between image capture and robot movement, reducing latency and improving cycle consistency. Compact design and moderate power requirements also make integration easier in space-constrained robotic cells, enhancing overall system flexibility and reliability.

5. Traffic Monitoring and Intelligent Transport Analysis

Monitoring vehicles in motion presents challenges due to speed, lighting variation, and wide scene coverage. A 9 MP global shutter sensor captures clear, undistorted images of moving vehicles, supporting accurate analysis across multiple lanes with fewer cameras. High resolution allows fine details to be resolved over large areas, improving data quality for traffic flow assessment or vehicle classification. Adjustable exposure helps adapt to changing light conditions throughout the day. Consistent triggering and stable image acquisition ensure dependable data collection for scalable transportation monitoring systems.

Related Products & Accessories

IDS Accessories

-

C-Mount Industrial Lenses – Suitable for 1″ sensor coverage with high optical resolution

-

GigE Ethernet Cables – Reliable data transmission for long cable runs

-

Power over Ethernet Injectors – Single-cable solution for power and data

-

8-Pin Hirose I/O Cables – For trigger, flash, and GPIO synchronization

-

Industrial Lighting Controllers – Supports hardware-triggered strobe lighting

IDS Imaging Cameras

-

UI-5280SE Series – Global shutter GigE cameras for cost-optimized systems

-

UI-5240SE Series – Compact GigE cameras for space-constrained applications

Contact US

As an authorized distributor of IDS products, we offer certified expertise and technical support to ensure you get the most out of your UI-5292SE Rev.4.2 camera. We stand by the quality of our products and provide comprehensive warranty services. Our team can also assist with special services like custom integration and creating pre-configured kits tailored to your specific needs.

- Contact Us: Get in touch with our technical support team for detailed inquiries about the UI-5292SE Rev.4.2 ‘s features and integration.

- Request a Quote: Planning a large-scale project? Contact us for a bulk quote or OEM pricing.

- Download Software: Access the necessary software, APIs, and manuals to get started with your IDS camera.

- Email: sales@inosaki.com