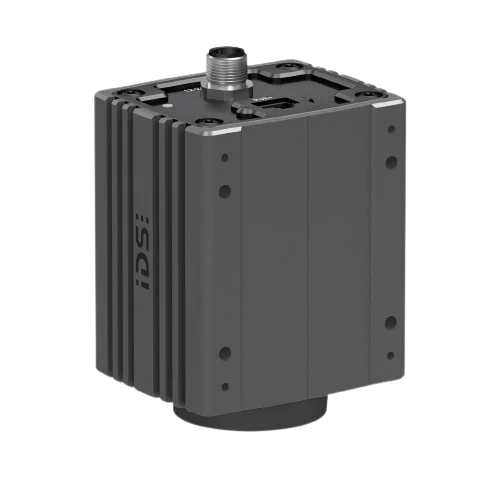

IDS Imaging GV-77U5WP – 45 MP Global Shutter GigE Vision Camera

Product Description

The IDS Imaging GV-77U5WP is a high-resolution 45 MP GigE Vision industrial camera developed for applications that require large-area imaging with absolute geometric accuracy. Built around a global shutter CMOS sensor, it delivers an 8200 × 5468 resolution that allows fine structures and defects to be captured clearly, even on moving objects. The Super 35 mm optical format supports professional industrial lenses, making the camera suitable for wide-field inspection, metrology, and high-precision measurement tasks in demanding environments.

With frame rates up to 32 fps, precise hardware triggering, and extensive onboard image processing, the GV-77U5WP ensures stable and repeatable results in automated systems. Features such as flexible exposure control, bandwidth management, and multi-camera synchronization enable efficient integration into complex inspection lines. These capabilities make it well suited for semiconductor inspection, flat-panel analysis, and advanced automation systems where accuracy, reliability, and scalability are essential.

Technical Capabilities

-

45 MP Global Shutter CMOS Sensor – 8200 × 5468 resolution for ultra-high-detail large-area inspection and precision measurement

-

Up to 27 fps @ Full Resolution – Consistent performance for high-resolution industrial imaging, with up to 32 fps in trigger mode

-

GigE Vision Interface – Long-distance, stable data transmission with bandwidth management for reliable real-time processing

-

Global Shutter Architecture – Distortion-free capture of fast-moving objects and conveyor-based applications

-

Advanced Image Control & Processing – Programmable exposure, gain, AOI, binning, denoising, LUT, and automatic adjustments

-

Industrial SDK & GenICam Support – Seamless integration into machine vision systems via the IDS Imaging software ecosystem

Specifications

- Color: GV-77U5WP-C-HQ (AB03375)

- Mono: GV-77U5WP-M-GL (AB03374)

| Feature | Details | Application Advantage |

|---|---|---|

| Sensor Brand & Model | onsemi NOIX1SE045KB-GTI (Color) / NOIX1SN045KB-GTI (Mono) | High-end CMOS sensor ensures stable performance and long-term availability |

| Interface | GigE Vision (RJ45) | Reliable long-distance data transmission for industrial systems |

| Interface Speed | Gigabit Ethernet with bandwidth management | Stable image streaming without frame drops |

| Resolution (H × V) | 8200 × 5468 pixels (44.84 MP) | Captures extremely fine details in a single image |

| Optical Area (H × V) | 26.214 × 17.472 mm | Covers large inspection areas efficiently |

| Optical Format | Super 35 mm (2″ diagonal 31.5 mm) | Supports professional large-format industrial lenses |

| Lens Mount | TFL (M35 × 0.75) | Secure mounting for high-resolution optics |

| Pixel Size | 3.2 µm | Balanced sensitivity and resolution for precision imaging |

| Image Memory | 2032 MB | Enables buffering for high-resolution continuous capture |

| Frame Rate @ Max. Resolution | 27 fps (up to 32 fps trigger mode) | Suitable for high-speed inspection with full resolution |

| Shutter | Global shutter | Distortion-free imaging of moving objects |

| Exposure Time | 0.042 ms to 2000 ms | Flexible control from fast motion to low-light scenes |

| Trigger & Flash I/O | 12-pin M12 with optocoupled trigger and flash outputs | Precise synchronization with external devices and lighting |

| Power Supply | 12–24 V DC or PoE+ | Simplified cabling and flexible power options |

| Software Tools | IDS peak with AOI, binning, decimation, LUT, auto functions | Reduces host load and speeds up system development |

| Environmental Tolerance | Operating: 0 °C to 55 °C, 20–80% RH (non-condensing) | Reliable operation in industrial environments |

| Housing Protection | IP30, aluminum housing | Robust mechanical design for factory use |

| Size & Weight | 60 × 75 × 94.5 mm, approx. 570 g | Compact form factor for easy integration |

- Download IDS GV-77U5WP-C-HQ Datasheet

- Download IDS GV-77U5WP-M-GL Datasheet

- Download IDS GV-77U5WP Technical Drawing

Ideal Applications

1. Large-Area Semiconductor Wafer Inspection

In semiconductor fabrication, inspecting full wafers demands extremely high resolution without the complexity of image stitching. The GV-77U5WP allows entire wafer surfaces to be captured in a single exposure, preserving positional accuracy across the field of view. Its global shutter freezes motion during transport, ensuring that defect locations remain precise. Fine pixel resolution reveals micro-level scratches, particles, and pattern deviations that smaller sensors often miss. Accurate hardware triggering aligns image capture with wafer movement, while flexible exposure control supports uniform illumination. This approach improves defect detection reliability and reduces mechanical and optical system complexity.

2. Flat Panel Display and Glass Surface Inspection

Manufacturers of flat panels and glass surfaces must detect subtle defects across large, reflective areas. The GV-77U5WP captures wide surfaces in one frame, avoiding errors caused by multi-image scanning. Its large optical format supports lenses that maintain sharpness from center to edge, which is critical for consistent inspection. Global shutter operation prevents distortion when panels move continuously through production lines. Adjustable exposure settings and image processing functions help manage reflections and uneven lighting. As a result, inspection systems achieve higher consistency, faster cycle times, and more reliable defect classification.

3. High-Precision Dimensional Metrology Systems

Dimensional metrology applications rely on stable geometry and dense image data for accurate measurement. The GV-77U5WP provides a high pixel count that enables precise measurements across large components without repositioning. Global shutter imaging preserves true dimensions even when objects are in motion on measurement stages. Large onboard image memory supports continuous acquisition, while precise triggering ensures alignment with external position references. These capabilities allow accurate measurement of large mechanical parts, plates, or composite structures, improving repeatability and reducing overall measurement uncertainty.

4. Printed Circuit Board and Substrate Inspection

Advanced printed circuit boards often exceed the viewing limits of conventional cameras, making inspection slow and complex. The GV-77U5WP captures high-density layouts in a single image, enabling simultaneous evaluation of traces, vias, and surface quality. Motion-induced distortion is eliminated by the global shutter, even when boards move through automated inspection stations. High resolution exposes fine copper patterns and small defects, while region-of-interest control allows performance optimization for critical areas. This results in faster inspection, simplified system design, and improved detection accuracy in electronics manufacturing.

5. Industrial Large-Object Imaging and Documentation

Industrial environments often require detailed imaging of large assemblies or structures for documentation and analysis. The GV-77U5WP enables high-detail capture of large objects without relying on panoramic stitching, preserving spatial accuracy. Its flexible exposure range supports challenging lighting conditions found in production halls and testing facilities. Global shutter technology ensures sharp images even when vibration or motion is present. These characteristics make it suitable for quality documentation, automated visual records, and inspection of oversized components where clarity, consistency, and precision are essential.