Key Features & Specifications – IDS Imaging GV-51J2SE Rev.4.2 [Color: 1009723 | Mono: 1009724]

| Feature | Details | Benefit |

|---|---|---|

| Sensor Brand & Model | Sony IMX546 (Color: IMX546-AAQJ-C / Mono: IMX546-AAMJ-C) | Proven industrial sensor delivers stable image quality and long-term availability |

| Sensor Type | CMOS, Global Shutter | Eliminates motion distortion for accurate inspection and measurement |

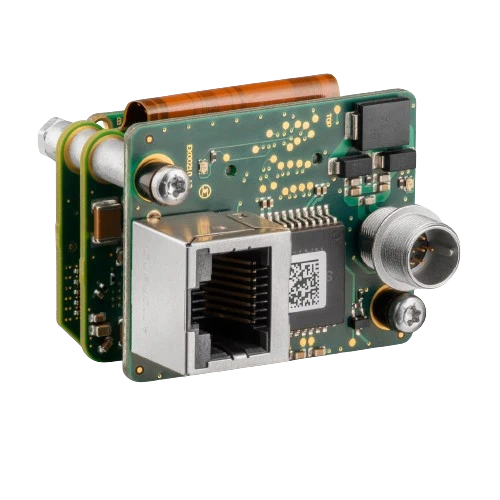

| Interface | GigE Vision (RJ45) | Reliable long-distance data transfer for factory-floor deployments |

| Interface Speed | Gigabit Ethernet (1 Gbps) | Stable bandwidth for consistent image streaming |

| Resolution (H × V) | 2856 × 2848 pixels (8.1 MP) | High spatial detail for precision inspection tasks |

| Aspect Ratio | 1:1 (square sensor) | Efficient field coverage for metrology and AOI applications |

| Optical Area (H × V) | 7.825 mm × 7.804 mm | Optimized active area for high-resolution imaging |

| Optical Format | 2/3″ (Diagonal 11.05 mm) | Broad compatibility with industrial lenses |

| Pixel Size | 2.74 µm | Good balance between sensitivity and resolution |

| Lens Mount | No mount (board-level design) | Maximum flexibility for custom optical integration |

| Image Memory | 128 MB | Supports buffering for triggered and synchronized capture |

| Frame Rate @ Max. Resolution | Up to 15 fps (16 fps trigger peak) | Suitable for moderate-speed inspection and automation |

| Shutter | Global Shutter | Accurate capture of fast-moving objects |

| Exposure Time | 0.023 ms to 2000 ms (up to 120 s long exposure) | Supports both high-speed and low-light imaging |

| Trigger & Flash I/O | Hardware trigger, opto-isolated trigger and flash outputs | Precise synchronization with encoders and lighting |

| Power Supply | 12–24 V DC or Power over Ethernet (PoE) | Simplified cabling and installation |

| Software Tools | IDS peak SDK, on-host image processing | Flexible configuration and integration into vision systems |

| Environmental Tolerance | Operating 0 °C to 55 °C, 20–80% RH (non-condensing) | Reliable operation in industrial environments |

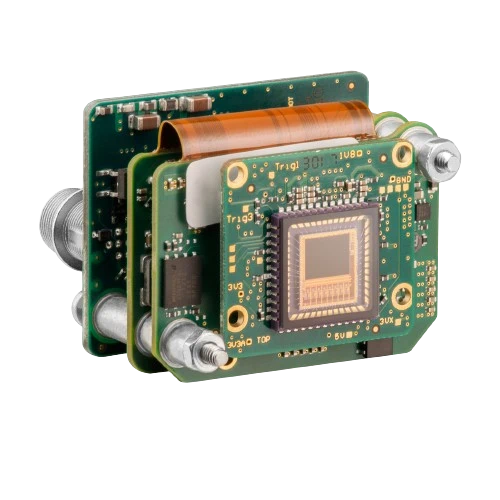

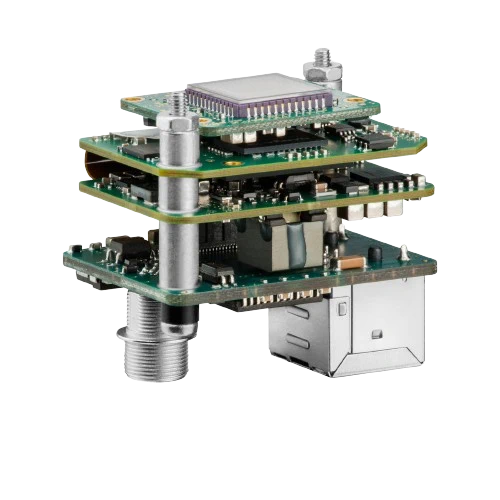

| Housing Protection | Open PCB module | Ideal for embedded systems and OEM designs |

| Size & Weight | 31.5 × 40.0 × 30.0 mm, approx. 22 g | Compact and lightweight for space-constrained systems |

Download IDS GV-51J2SE-C Rev.4.2 (1009723) Datasheet

Download IDS GV-51J2SE-M Rev.4.2 (1009724) Datasheet

Download IDS GV-51J2SE Rev.4.2 Technical Drawing

The Applications

1. Precision Dimensional Measurement in Automated Metrology

In automated metrology, even small geometric errors can lead to rejected parts or costly rework. Systems using the Sony IMX546 global shutter sensor capture all pixels at the same instant, ensuring that measurements remain accurate even when components are in motion. The square 8.1 MP resolution makes efficient use of the sensor area for round or symmetric parts, while high bit-depth imaging improves edge clarity for sub-pixel calculations. When synchronized with motion stages through hardware triggering, the camera delivers repeatable, distortion-free data that supports reliable dimensional verification in continuous production environments.

2. PCB and Electronics Inspection with Synchronized Lighting

Electronics inspection often depends on precisely timed lighting to reveal solder joints, fine traces, and surface defects. The IMX546 global shutter sensor enables clean image capture under short strobe pulses without partial exposure artifacts. Its high resolution supports inspection of densely populated boards, while accurate trigger and flash control ensure lighting and image acquisition remain perfectly aligned. This combination reduces motion blur and improves defect visibility, allowing automated inspection systems to detect subtle issues such as insufficient solder, misalignment, or surface contamination during high-throughput electronics manufacturing.

3. Vision-Guided Robotic Pick-and-Place Operations

Robotic pick-and-place systems rely on accurate visual information to locate, orient, and grasp parts on moving conveyors. Cameras based on the IMX546 sensor provide distortion-free images that preserve true object shape, which is critical for calculating precise pick points. The resolution supports reliable object recognition, while consistent triggering allows synchronization with conveyor motion. Stable GigE data transmission ensures dependable image delivery across industrial work cells, helping robots maintain placement accuracy and reduce errors even in fast-paced automated assembly lines.

4. Surface Inspection of Reflective or Metallic Components

Inspecting reflective materials such as polished metal or coated parts requires precise timing and controlled exposure to manage glare and subtle contrast changes. The IMX546 sensor supports synchronized lighting and flexible exposure control, allowing images to be captured at optimal moments. Fine pixel resolution reveals small surface imperfections like scratches, dents, or coating irregularities. Global shutter operation prevents distortion during movement, enabling consistent surface analysis in quality control systems where appearance and finish directly affect product acceptance.

5. Laboratory Automation and Scientific Imaging

In laboratory and research environments, consistency and timing accuracy are critical for reliable data collection. The IMX546 global shutter sensor provides a stable, linear response suitable for quantitative imaging tasks. Its ability to capture motion without temporal distortion supports observation of moving samples or transient events. Long exposure capability expands use in low-light experiments, while precise triggering enables synchronization with external instruments. These characteristics make the sensor well suited for automated microscopy, sample inspection, and controlled laboratory workflows where data integrity is essential.

Related Products & Accessories

IDS Accessories

-

C-Mount Lenses – Optimized for 2/3″ sensors and high-resolution global shutter imaging

-

GigE Vision Cables & PoE Switches – Stable power and data transmission for single or multi-camera systems

-

Hirose 8-pin I/O Cables – Hardware trigger and flash synchronization support

-

Industrial LED / Strobe Lighting – Matched for global shutter capture and precise timing

-

IDS peak SDK – Configuration, acquisition, and host-side image processing

IDS Imaging Cameras

-

GV-51J2SE Series – 8.1 MP Sony IMX546 global shutter, GigE Vision

-

U3-3271LE Series – 3.2 MP IMX265 in compact USB3 format