VUVG-S14-P53C-H-G18-1R8L – Air Solenoid Valve – Festo Directional Control Valves

¥ 12,961.65 ¥ 10,628.55

Manufacturer Part Number: Festo 564212 #12

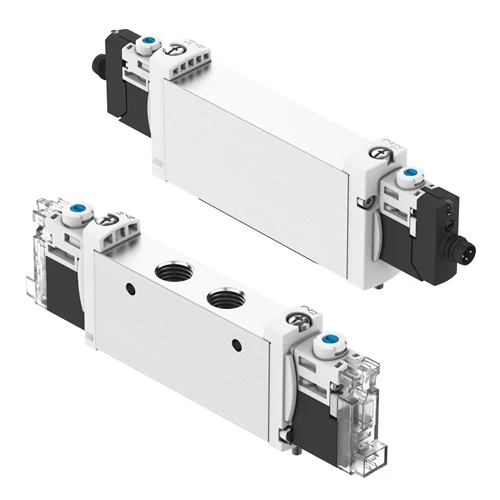

Festo Directional Control Valves: VUVG-S14-P53C-H-G18-1R8L

OEM Spec Ref

The Festo VUVG-S14-P53C-H-G18-1R8L Directional Control Valve, with MPN 564212, is a state-of-the-art pneumatic control device crafted to deliver superior precision and reliability in regulating airflow within various industrial systems. This valve is engineered to function seamlessly across diverse applications, promoting optimized operational performance and enhanced system reliability.

Key Features:

- Accurate Airflow Control: Designed to offer meticulous control over airflow, this valve helps in maintaining precise operating conditions, ensuring optimal performance at all times.

- Sturdy Construction: Made from high-quality materials, the VUVG-L10-P53C-T-M5-U-1H2L-W1 is built to endure the demanding conditions of industrial environments, offering durability and long service life.

- Space-Saving Design: Its compact design makes it an excellent choice for installations within limited spaces, without compromising on its efficiency or effectiveness.

- Simple Adjustment: This valve features user-friendly adjustment mechanisms that allow for quick and precise setting changes, facilitating easy system calibration and maintenance.

- Wide Compatibility: It is designed to integrate smoothly with various pneumatic systems, making it a versatile option for numerous industrial applications.

Benefits:

- Enhanced System Efficiency: By ensuring precise control over air direction and flow, this valve boosts the efficiency and reliability of pneumatic operations, improving overall system performance.

- Lower Operational Costs: Optimizing airflow control helps reduce energy use and operational costs, contributing to more economical system management.

- Increased Component Longevity: Proper airflow management reduces stress on system components, prolonging their lifespan and decreasing the need for frequent maintenance.

- Improved Safety: Reliable operation and precise control contribute to safer system functions, meeting stringent safety standards and reducing risk factors in industrial settings.

Applications:

- Automated Production Lines: Crucial for maintaining accurate control in automated manufacturing environments, ensuring high-quality production and operational consistency.

- Pneumatic Control Systems: Plays an essential role in systems requiring stable and precise airflow for proper functionality.

- Testing and Quality Assurance: Ideal for applications demanding consistent air flow for accurate testing and inspection, crucial in quality assurance processes.

- Diverse Industrial Applications: Well-suited for a wide array of pneumatic applications across various industries, enhancing precision and operational reliability.

The Festo VUVG-S14-P53C-H-G18-1R8L Directional Control Valve exemplifies Festo’s commitment to advancing pneumatic technology, offering a robust solution for managing airflow and enhancing the performance of industrial processes. This valve is a key component in ensuring the efficient and safe operation of pneumatic systems in any industrial setting.

Technical Data

| Feature | Specification |

|---|---|

| Valve function | 2×3/2, closed, monostable 2×3/2, open, monostable 2×3/2, open/closed, monostable 5/2, bistable 5/2, monostable 5/3, pressurized 5/3, exhausted 5/3, closed |

| Actuation type | Electrical |

| Valve size | 14 mm |

| Standard nominal flow rate | 90 l/min … 1380 l/min |

| Pneumatic working port | Flange M3 M5 M7 G1/8 G1/4 QS-3 QS-4 QS-6 QS-8 QS-10 QS-5/32 QS-1/8 QS-3/16 QS-1/4 QS-5/16 QS-3/8 |

| Operating voltage | 12V DC 24V DC 5V DC |

| Operating pressure | -0.09 MPa … 1 MPa |

| Operating pressure | -0.9 bar … 10 bar |

| Structural design | Piston gate valve Piston slide with sealing ring |

| Reset method | Mechanical spring Pneumatic spring |

| Certification | RCM compliance mark c UL us – Recognized (OL) |

| CE marking (see declaration of conformity) | As per EU EMC directive As per EU low voltage directive As per EU RoHS directive |

| UKCA marking (see declaration of conformity) | To UK instructions for EMC To UK RoHS instructions To UK instructions for electrical equipment |

| Degree of protection | IP40 IP65 With plug socket |

| Exhaust air function | With flow control option |

| Sealing principle | Soft |

| Mounting position | Any |

| Manual override | Detenting Non-detenting Covered |

| Type of control | Pilot-controlled |

| Pilot air supply port | External Internal |

| Lap | Overlap Indefinite overlap |

| Duty cycle | 100% |

| Permissible voltage fluctuations | +/- 10 % |

| Operating medium | Compressed air as per ISO 8573-1:2010 [7:4:4] |

| Information on operating and pilot media | Operation with oil lubrication possible (required for further use) |

| Restricted ambient and media temperature | -5 – 50 °C Without holding power reduction |

| Corrosion resistance class (CRC) | 0 – No corrosion stress 2 – Moderate corrosion stress |

| LABS (PWIS) conformity | VDMA24364-B1/B2-L VDMA24364 zone III |

| Temperature of medium | -5 °C … 60 °C |

| Ambient temperature | -5 °C … 60 °C |

| Electrical connection | Via electrical sub-base |

| Type of mounting | Optionally: On terminal strip With through-hole |

| Note on materials | RoHS-compliant |

| Seals material | HNBR NBR |

| Housing material | Wrought aluminum alloy |