Panasonic | INDUSTRY

ER-VW Series

Thin-type Ionizer ER-VW

Panasonic ER-VW Thin Type Ionizer | High-Frequency AC Static Eliminator

The Panasonic ER-VW Thin Type Ionizer is a compact, high-efficiency electrostatic eliminator designed for modern production lines where precision and space are critical. Using a 68 kHz high-frequency AC discharge method, it ensures fast, stable charge removal without damaging sensitive electronic components. Its slim 18.9 mm body and 190° adjustable dual nozzles provide unmatched flexibility for installation in tight or multi-axis setups. Multiple ER-VW units can be connected using Panasonic’s modular joint system, enabling seamless coverage across conveyors, IC trays, or optical assembly lines. With low air consumption, smart monitoring, and long-life tungsten needles, the ER-VW delivers consistent static control performance — making it an essential choice for cleanroom, semiconductor, LCD, and precision manufacturing environments.

Key Performance & Design

Compact and Thin Design

Suitable for both single-point and multi-station integration

Allows installation in narrow or enclosed environments without performance loss

Adjustable Nozzle with Wide-Angle Flexibility

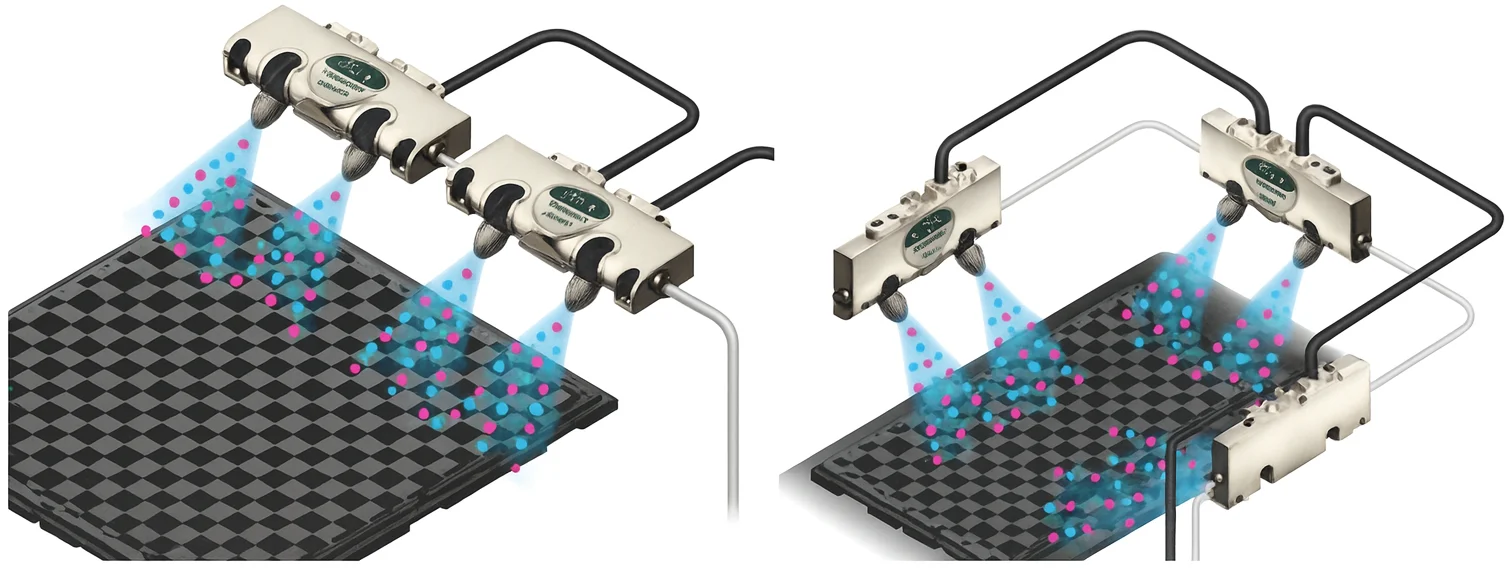

Every ER-VW unit is equipped with dual precision nozzles that can be freely adjusted within a 190-degree range. This design lets operators target static charges from virtually any direction, ensuring complete coverage of uneven or complex surfaces. The built-in angle adjustment scale allows repeatable positioning, making calibration easy after cleaning or maintenance. Whether mounted horizontally on a conveyor or vertically in an inspection cell, the flexible nozzle layout ensures efficient static neutralization in every setup.

190° angle adjustment for accurate discharge positioning

Quick locking mechanism maintains stable angle during continuous operation

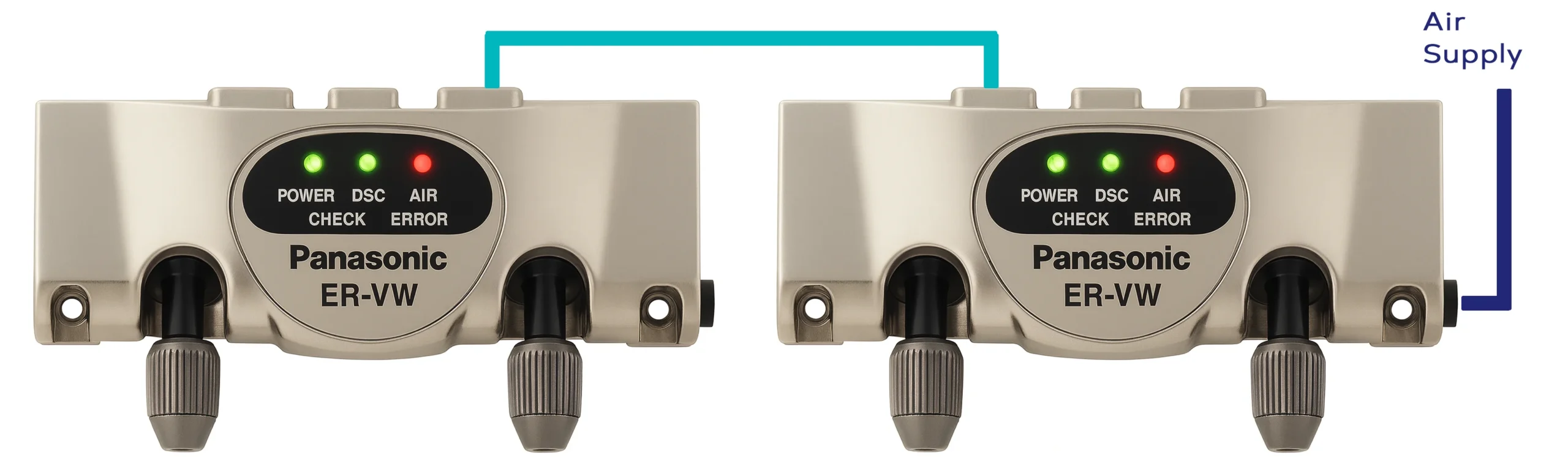

Flexible and Efficient Connection Layout

The ER-VW’s modular connection architecture enables simple expansion of your charge-removal area. Using the optional joint kit (ER-WWAR80), up to five ionizer units can be linked together with shared air and power lines. This reduces cabling complexity and minimizes air-supply tubing, simplifying system layout while maintaining uniform ion performance across the line. Quick-connection joints and dedicated 8-pin connector cables make setup faster and more reliable, allowing production teams to design a clean, efficient configuration that suits their exact equipment footprint.

Scalable system design for larger or irregular work areas

Unified air and power routing for minimal maintenance effort

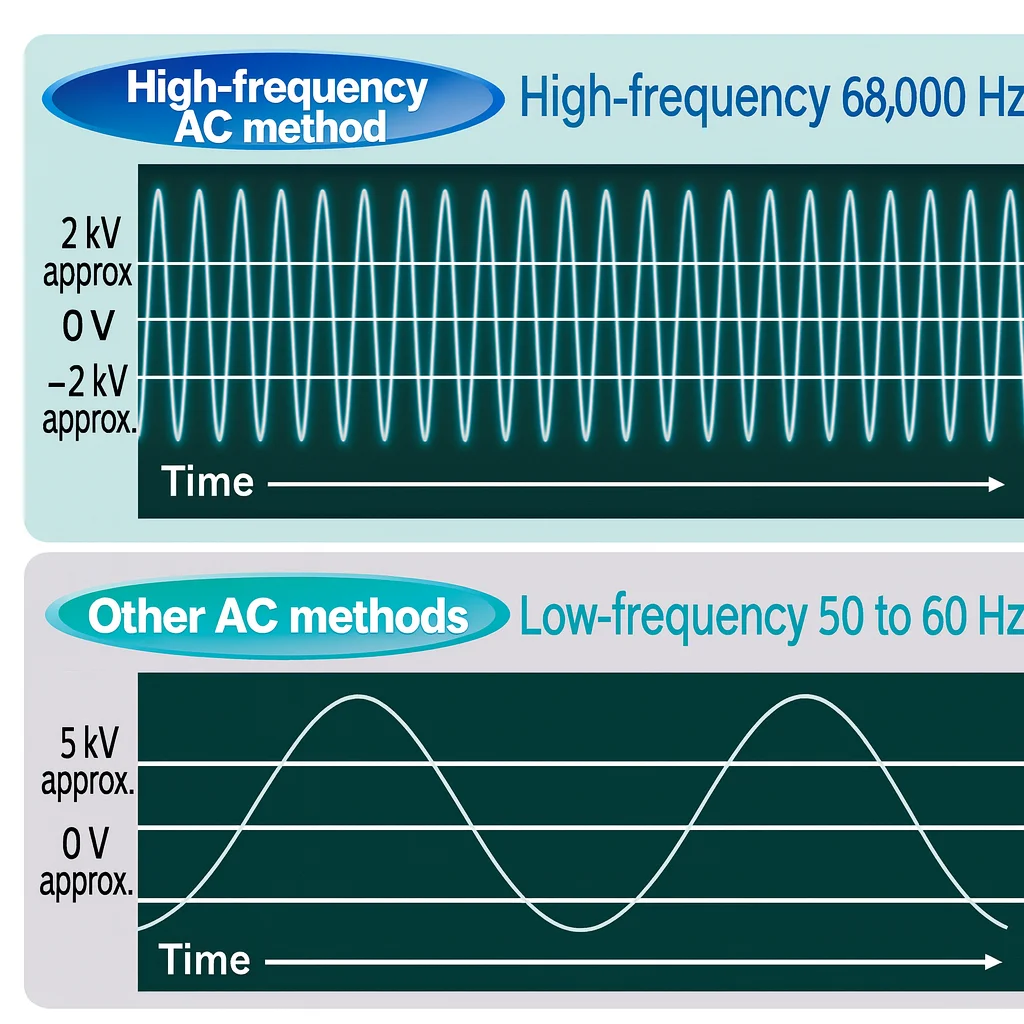

Stable Ion Balance with High-Frequency AC Method

The ER-VW employs Panasonic’s 68 kHz high-frequency AC discharge method, alternating positive and negative ions in rapid succession. This technology ensures perfect ion balance, minimizing localized charging and eliminating the risk of reverse polarity that can damage sensitive components. The stable discharge pattern maintains consistent neutralization even when air conditions fluctuate. As a result, operators achieve uniform electrostatic control without complicated adjustments or periodic recalibration.

±10 V or less ion balance guarantees stable charge removal

Prevents inverse charging and maintains high-yield production quality

INTELLIGENT OPERATION

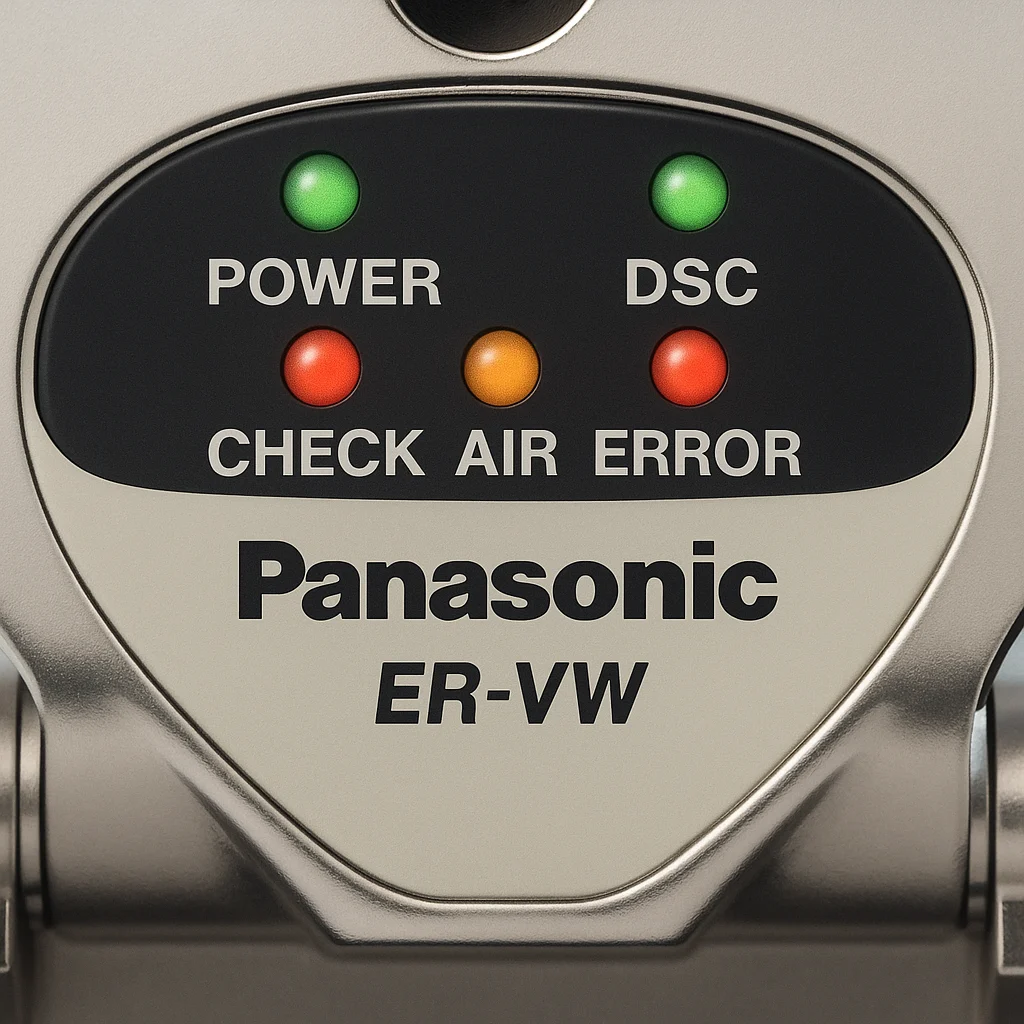

Air Supply & Discharge Monitoring

To maintain safe, consistent operation, the ER-VW includes built-in air-supply monitoring and intelligent discharge control. The unit automatically halts ion emission if air pressure drops below the preset threshold, preventing undetected loss of charge-removal capability. Multiple status indicators — POWER, AIR, CHECK, and ERROR LEDs — provide instant visual feedback, while output signals can be linked to PLC systems for real-time monitoring. These smart safeguards protect both equipment and products by ensuring every discharge cycle operates under optimal conditions.

Air Supply Monitoring (DSC)

Automatically stops discharge if air supply drops below a certain pressure, preventing overcharged objects which can occur if only ions of one polarity are discharged without air assistance.

Discharge Monitoring (ERROR/CHECK)

Triggers an alarm (ERROR/CHECK) if a high-voltage abnormality occurs or if the discharge needle is dirty/faulty, allowing for immediate corrective action.

Maintenance-Friendly Design and Accessory Options

Routine maintenance is simplified with a replaceable tungsten discharge needle unit (ER-WWANT) that ensures consistent ion performance over long operating periods. Optional mini line filters (ER-AF10 / ER-AF20) remove fine dust and oil particles from the air supply to maintain stable discharge quality. Panasonic’s accessory range — including 2 m to 9 m connector cables and modular joint kits — allows flexible installation in virtually any industrial layout. The ER-VW is designed for easy serviceability, reducing downtime and ensuring long-term reliability in demanding production environments.

Tool-free replacement of discharge needle unit

Optional air filters and connectors maintain consistent performance

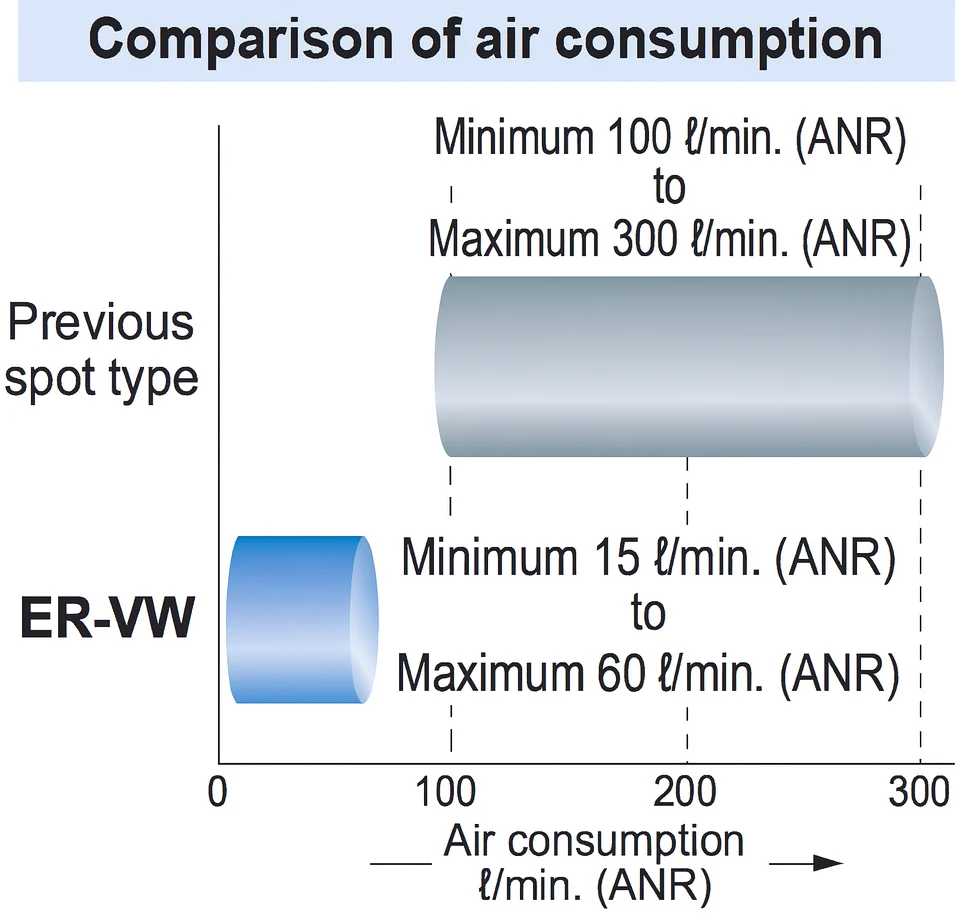

Low Air Consumption and Energy Efficiency

Engineered for long-term cost savings, the ER-VW can operate effectively with an air flow as low as 15 L/min (ANR), dramatically lower than conventional ionizers that require 100 L/min or more. This reduction cuts the load on compressed-air systems, reduces energy consumption, and prolongs the service life of filters and regulators. Even at minimal flow rates, the ER-VW delivers strong, consistent ionization, making it an ideal solution for cleanroom or precision manufacturing environments where both efficiency and air quality are vital.

Operates from 15 L/min to 60 L/min, ensuring flexible performance control

Reduces compressed-air cost and noise in continuous operations

Key Features & Specifications

| Feature | Details | Benefit |

|---|---|---|

| Model Type | ER-VW (Spot Type Ionizer) | Designed for localized electrostatic charge removal |

| Discharge Method | High-frequency AC (68 kHz) | Generates stable positive/negative ion balance for uniform discharge |

| Charge Removal Time | ≤ 1 sec (± 1000 V → ± 100 V at 100 mm) | Fast neutralization for sensitive device handling |

| Ion Balance | ± 10 V or less | Prevents inverse charging and protects electronics |

| Nozzle Adjustment Range | Approx. 190° adjustable | Flexible discharge angle for vertical or horizontal mounting |

| Air Flow Range | 15 – 60 L/min (ANR) | Minimal air consumption for lower operational cost |

| Air Pressure Range | 0.05 – 0.5 MPa | Works with standard clean-air supply |

| Supply Voltage | 24 V DC ± 10 % | Low-voltage safe operation |

| Current Consumption | 120 mA or less | Energy-efficient performance |

| Certifications | CE, UKCA, TÜV SÜD (U.S.A., Canada) | International compliance with EMC / RoHS directives |

| Material | Stainless-steel nozzle, Tungsten needle | Durable, corrosion-resistant components |

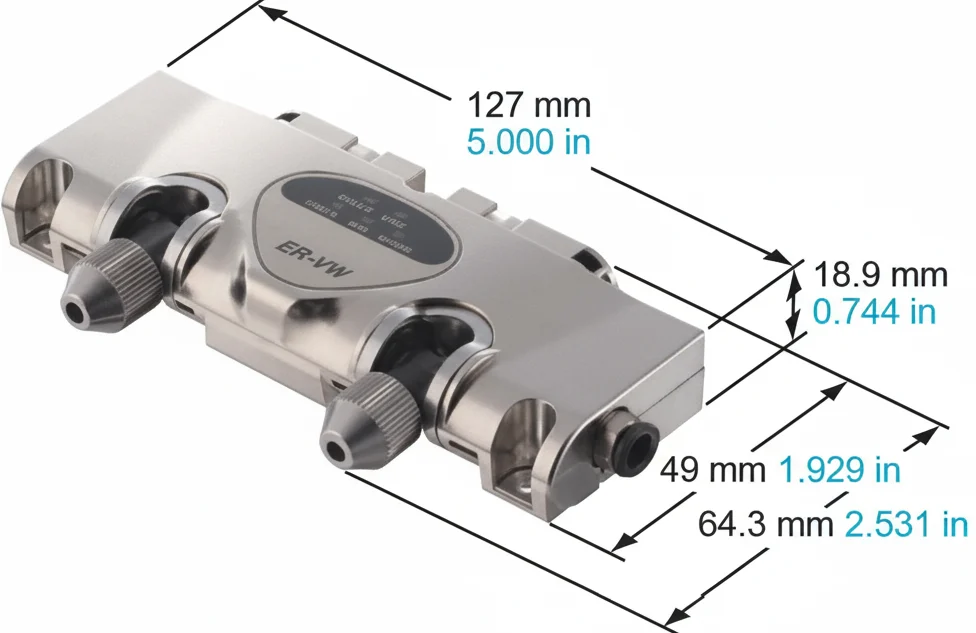

| Dimensions (W × D × H) | 127 × 49 × 18.9 mm | Compact and ultra-thin body for tight installation |

| Weight | Net 110 g approx. | Lightweight and easy to mount |

| Connection Capability | Up to 5 units (ER-VW) via joint kit | Scalable modular setup for wider coverage |

| Operating Conditions | 0 – +55 °C, 35 – 65 % RH | Reliable performance in factory environments |

Available Accessories

| Accessory | Model No. | Description / Use |

|---|---|---|

| Connector Cable | ER-VWCC2 / ER-VWCC5 / ER-VWCC9 | 2 m / 5 m / 9 m cables for power & signal connection |

| Mini Line Filter | ER-AF10 / ER-AF20 | Removes particles > 0.1 µm from air supply; ensures clean airflow |

| Discharge Needle Unit | ER-WWANT | Replacement tungsten needles (2 per set) |

| Joint Kit | ER-WWAR80 | Connects multiple ER-VW units for modular layout |

Commercial Information

| Attribute | Details |

|---|---|

| Brand | Panasonic |

| Model | ER-VW |

| GTIN Number | — (to be updated when available) |

| Traffic Number | — (to be updated when available) |

| Weight | 180 g (gross) |

| Country of Origin | Japan |

| Certifications | CE / UKCA / TÜV SÜD |

| Standard Warranty | 1 Year (extendable as per manufacturer policy) |

Applications Detail

1. Semiconductor / IC Handling & Packaging

In semiconductor fabrication lines, static charges on IC trays, wafer carriers, or encapsulated modules can cause delicate components to stick, misalign, or even suffer latent ESD damage. The ER-VW Thin Type Ionizer neutralizes surface charge quickly and uniformly, ensuring safe, stable transfer through pick-&-place, testing, or packaging stations. Its slim design allows installation around tight tool entrances or between robotic arms. Where multiple trays move side by side, modular connection lets several ER-VW units cover the width. With stable ion balance even under variable airflow, contamination and reject rates due to static adhesion are greatly reduced.

2. LCD / Display Module Assembly

In the manufacturing of LCD, OLED, or other display modules, glass substrates and flexible films are prone to static accumulation during handling or insertion steps. Static can attract dust, cause sticking, or interfere with optical alignment. The ER-VW device can be positioned near clamp frames or along glass transport paths to neutralize the charge ahead of inspection or bonding. Its thin profile ensures it doesn’t obstruct viewing or edge sensors. The adjustable nozzles let you direct ion flow even on angled surfaces. By eliminating static at critical stages, yield improves and defects from particulate contamination decline.

3. Optical Media & Coating Processes

During disk coating, polishing, or optical film deposition (e.g. for CDs, DVDs, Blu-rays, lenses), static charges can attract fine particles or disturb coating uniformity. The ER-VW ionizer neutralizes charge near the substrate just before coating or spinning, preventing dust adhesion or film defects. Its rapid response (≤ 1 second neutralization) ensures even fast-moving sheets or discs are neutral before processing. Multiple linked units can be aligned around holders to provide balanced ionization from multiple angles. Its low air consumption helps maintain laminar flow and avoid airflow disturbance in coating chambers.

4. Plastics, Film, and Sheet Processing

In extrusion, cutting, or converting of plastic films and sheets, static charge causes sheets to cling, curl, or misfeed. This leads to waste, production downtime, or material misalignment in subsequent steps (printing, laminating). The ER-VW module can be placed immediately after cutter, slitter, or reel to neutralize static before the next stage. Its compact form factor allows it to fit close to nip rollers or guiding edges. With its adjustable nozzle and modular capability, you can span wide webs or target edges where static is worst. The consistent ion balance avoids over- or under-neutralization across the film width.

5. Precision Assembly & Lead Frame / Surface Mount Lines

On PCB, lead frame, or connector assembly lines, static adhesion can cause small parts (screws, contacts, pins) to stick unexpectedly to tools or fixtures. This static interference causes misfeeds or assembly errors. The ER-VW ionizer targets these zones—such as feeding lanes, insertion points, or pick-up heads—to remove charge just before component handling. Because the ER-VW is very thin, it can mount close to compact tooling without blocking motion or vision systems. When more coverage is needed, multiple units can be connected to cover longer assembly zones.

6. Cleanroom & Inspection / Metrology Chambers

In cleanrooms or precision inspection / metrology chambers (e.g. microscopes, wafer inspection, optical measurement), foreign particle adhesion due to static is a silent yield killer. The ER-VW can be installed inside or just outside enclosed inspection zones to neutralize the environment before measurement. Its low air demand means minimal disruption to cleanroom airflow. The device’s stability ensures ion balance even under low humidity or temperature swings typical in cleanrooms. Because of its compactness, mounting inside enclosures or on fixture frames is feasible without interfering with instrumentation or calibration.

Contact Us

For technical assistance, maintenance service, or to purchase the Panasonic ER-VW Thin Type Ionizer, please reach out to our team.

Our engineers can help you confirm model compatibility, connection layout, and accessory requirements before ordering.

Email: sales@inosaki.com

Product Page: ER-VW Series – Panasonic Thin-type Ionizer