IDS Imaging U3-3890CP Rev.2.2 USB3 Vision Camera with 12 MP Sony IMX226

Product Overview

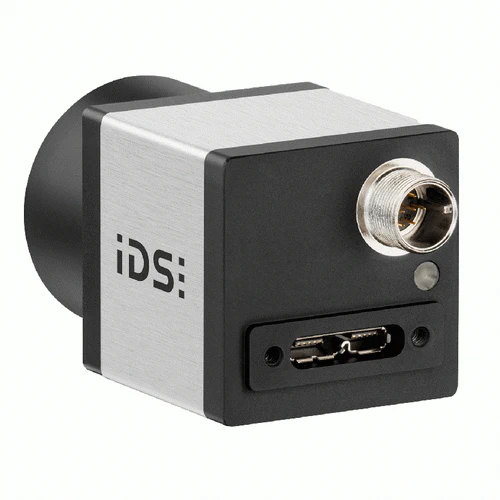

The IDS Imaging U3-3890CP Rev.2.2 is a compact industrial USB3 Vision camera engineered for applications that require high-resolution imaging in limited installation space. Equipped with a 12 MP Sony IMX226 CMOS sensor, it solves the challenge of capturing fine structural details while maintaining stable data throughput and precise control. With a native resolution of 4000 × 3000 pixels, 12-bit image depth, and a robust USB 3.0 interface, this camera delivers reliable, low-noise image data for demanding machine vision environments, all within a durable 29 mm cubic housing suitable for long-term industrial deployment.

Product Description

In practical machine vision systems, the U3-3890CP Rev.2.2 provides flexibility and performance without added system complexity. The small 1.85 µm pixel size enables accurate detection of subtle features, while selectable binning and region-of-interest functions allow users to trade resolution for higher frame rates when required. Support for hardware and software triggering ensures precise synchronization with external processes, and extended exposure capability makes the camera effective even in low-light conditions. Integrated image processing features further reduce host workload, resulting in faster development cycles and stable long-term operation across inspection, measurement, and scientific imaging tasks.

Why IDS Imaging U3-3890CP Rev.2.2?

The IDS Imaging U3-3890CP Rev.2.2 is chosen when high-resolution detail must fit into a compact, industrial-ready camera platform. Its 12 MP Sony IMX226 sensor captures fine textures and small defects that lower-resolution cameras miss, while the USB3 interface ensures fast, stable data transfer. The robust metal housing, flexible triggering options, and advanced image control features make it a dependable choice for systems that demand precision, repeatability, and long-term availability in real production environments.

What problem does it solve?

This camera addresses the challenge of acquiring highly detailed images without increasing system size or complexity. In many inspection and measurement tasks, limited space and lighting conditions restrict camera selection. The U3-3890CP Rev.2.2 overcomes this by combining a high pixel count, sensitive small-pixel sensor, and long exposure support in a compact form factor. It enables accurate analysis, reliable synchronization with external equipment, and consistent image quality, even in constrained or low-light industrial setups.

Key Features & Specifications – IDS Imaging U3-3890CP Rev.2.2 [Color: AB12694, Mono: AB12695]

| Feature |

Details |

Benefit |

| Sensor Brand & Model |

Sony IMX226 (Color: IMX226CQJ-C / Mono: IMX226CLJ-C) |

Proven Sony sensor ensures stable image quality and long-term availability |

| Interface |

USB3 Vision |

Wide compatibility and simple integration with industrial PCs |

| Interface Speed |

USB 3.0 (up to 5 Gbps) |

Enables fast data transfer for high-resolution imaging |

| Resolution (H × V) |

4000 × 3000 pixels (12 MP) |

Captures fine details for inspection, metrology, and documentation |

| Optical Area (H × V) |

7.40 mm × 5.55 mm |

Efficient sensor area for compact optics and precise imaging |

| Optical Format |

1/1.7″ (Diagonal 9.25 mm) |

Balanced format for high resolution in a compact camera body |

| Lens Mount |

C-Mount |

Broad lens compatibility and flexible system design |

| Pixel Size |

1.85 µm × 1.85 µm |

High spatial resolution for detecting small features |

| Image Memory |

128 MB on-board memory |

Smooth image buffering and stable acquisition |

| Frame Rate @ Max. Resolution |

Up to 33 fps (freerun) |

Supports high-throughput inspection at full resolution |

| Shutter |

Rolling shutter |

Optimized for speed and high-resolution performance |

| Exposure Time |

0.04 ms to 30,000 ms |

Effective imaging from bright scenes to low-light conditions |

| Trigger & Flash I/O |

Hardware & software trigger, opto-isolated I/O |

Precise synchronization with external equipment |

| Power Supply |

Via USB cable |

Simplifies wiring and reduces system complexity |

| Software Tools |

IDS peak SDK, on-host image processing |

Accelerates development and reduces CPU load |

| Environmental Tolerance |

Operating: 0 °C to 55 °C, 20–80% RH (non-condensing) |

Reliable operation in industrial environments |

| Housing Protection |

IP30, magnesium/stainless steel housing |

Durable construction for long-term industrial use |

| Size & Weight |

29 × 29 × 29 mm, approx. 48 g |

Extremely compact and lightweight for space-constrained systems |

Download IDS Imaging U3-3890CP-C-HQ Rev.2.2 (AB12694) Datasheet

Download IDS Imaging U3-3890CP-M-GL Rev.2.2 (AB12695) Datasheet

Download IDS Imaging U3-3890CP Rev.2.2 Technical Drawing

The Applications

1. High-Accuracy PCB Assembly Inspection

In modern electronics production, inspection systems must detect extremely small solder defects and component misalignment without slowing the line. Imaging systems based on the Sony IMX226 sensor are frequently applied in automated PCB inspection, where the 12-megapixel resolution reveals fine copper traces and solder fillets in a single capture. The high data throughput allows continuous image acquisition on moving conveyors, while region-of-interest control focuses processing on critical zones. This approach improves defect detection reliability, reduces false alarms, and supports consistent quality control in high-density electronics manufacturing environments.

2. Surface Quality Control for Manufactured Parts

Manufacturers of metal, plastic, and glass components often rely on high-resolution vision systems to identify minor surface imperfections. The Sony IMX226 sensor enables wide-area inspection with sufficient detail to expose scratches, dents, or texture variations that may affect product performance or appearance. Adjustable exposure and sensitivity support a range of lighting techniques, from bright field to low-contrast setups. Triggered image capture ensures consistent timing on moving parts, helping inspection systems maintain accuracy and repeatability in automated production lines.

3. Optical Metrology and Dimensional Verification

Precision measurement systems benefit from sensors that combine high pixel counts with stable output. The Sony IMX226 is commonly used in optical metrology solutions to support accurate edge detection and dimensional analysis. Its resolution allows measurement algorithms to resolve small features and apply sub-pixel calculations for improved accuracy. By limiting capture to selected image regions, systems can increase measurement speed without losing detail. This makes the sensor well suited for automated dimensional checks in machining, tooling inspection, and component verification processes.

4. Laboratory Imaging and Technical Documentation

In research and laboratory environments, cameras using the Sony IMX226 sensor support detailed documentation of experiments, samples, and test setups. The high resolution enables clear visualization of fine structures, while long exposure capability assists in low-light or controlled illumination conditions. Consistent sensor response helps ensure that captured images remain comparable over time, which is important for analysis and reporting. These characteristics make the sensor a practical choice for laboratories that require reliable, high-detail imaging without complex optical systems.

5. Compact Automation Cell Inspection Systems

Automation cells often have strict space constraints, yet still require comprehensive visual inspection. The Sony IMX226 sensor supports compact camera designs that can be mounted close to robotic tools or process stations. Its high resolution allows a single camera to cover a larger inspection area, reducing the need for multiple viewpoints. Precise triggering ensures images are captured at the correct moment in the cycle, even with variable process speeds. This improves inspection coverage while keeping system design simple and flexible for future changes.

Related Products & Accessories

IDS Accessories

-

C-Mount Lenses (IDS Approved) – Optimized for 1/1.7″ sensors to match the Sony IMX226

-

USB3 Vision Screw-Lock Cables – Secure, high-speed connectivity for industrial use

-

8-Pin Hirose I/O Cables – Supports hardware trigger, flash output, and GPIO control

-

Industrial LED Lighting (Strobe / Continuous) – Enables synchronized and uniform illumination

-

Mounting Brackets and Adapter Plates – Simplifies installation in compact machine vision systems

IDS Imaging Cameras

As an authorized distributor of IDS products, we offer certified expertise and technical support to ensure you get the most out of your U3-3890CP Rev.2.2 camera. We stand by the quality of our products and provide comprehensive warranty services. Our team can also assist with special services like custom integration and creating pre-configured kits tailored to your specific needs.

- Contact Us: Get in touch with our technical support team for detailed inquiries about the U3-3890CP Rev.2.2 ‘s features and integration.

- Request a Quote: Planning a large-scale project? Contact us for a bulk quote or OEM pricing.

- Download Software: Access the necessary software, APIs, and manuals to get started with your IDS camera.

- Email: sales@inosaki.com