Specifications

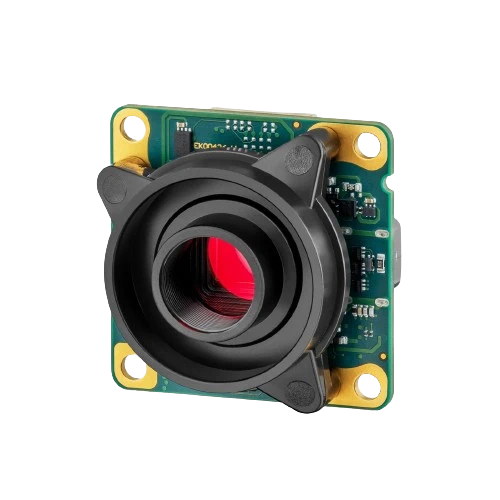

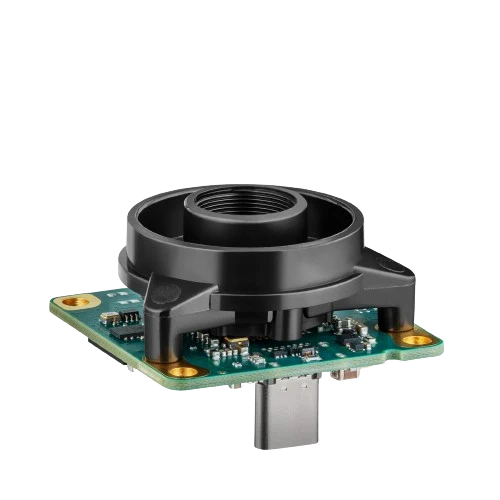

- Mono: U3-3681XLE-NIR-GL-VU Rev.1.2 (1009381)

| Feature | Details | Application Advantage |

|---|---|---|

| Sensor Brand & Model | onsemi AR0522 (Monochrome, NIR-optimized) | Enhanced sensitivity in near-infrared wavelengths for reliable feature detection beyond visible light |

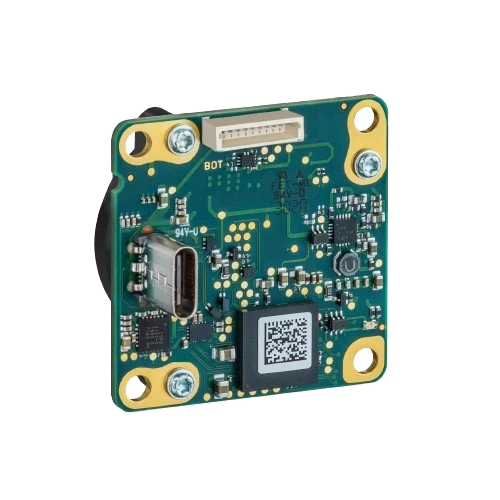

| Interface | USB3 (USB Type-C) | High-speed, plug-and-play connectivity for industrial PCs and embedded platforms |

| Interface Speed | USB 3.0 (up to 5 Gbps) | Supports high data throughput with low latency for real-time processing |

| Resolution (H × V) | 2592 × 1944 pixels (5.04 MP) | Precise detail capture for inspection, measurement, and analysis |

| Optical Area (H × V) | 5.702 mm × 4.277 mm | Optimized active imaging area for compact lens designs |

| Optical Format | 1/2.5″ (Diagonal 7.13 mm) | Broad compatibility with small-format industrial lenses |

| Lens Mount | S-Mount (M12) | Ideal for compact, space-constrained embedded systems |

| Pixel Size | 2.2 µm × 2.2 µm | Balanced sensitivity and resolution for accurate grayscale imaging |

| Image Memory | Not available (streaming mode) | Minimizes hardware complexity and power consumption |

| Frame Rate @ Max. Resolution | Up to 48 fps (freerun) | Enables smooth capture of dynamic or fast-moving processes |

| Shutter Type | Rolling shutter | Best suited for controlled-motion and synchronized imaging environments |

| Exposure Time | 0.01 ms to 635 ms | Supports both high-speed capture and low-light, long-exposure imaging |

| Trigger & Flash I/O | Hardware trigger, flash output, GPIO (8-pin connector) | Precise synchronization with external devices and lighting |

| Power Supply | Via USB (5 V, max. 400 mA) | Simplified system wiring and reduced external power requirements |

| Software Tools | IDS peak SDK, GenICam compliant | Easy integration, configuration, and long-term software support |

| Environmental Tolerance | Operating: 0 °C to +85 °C, 20–80% RH (non-condensing) | Reliable operation in demanding industrial environments |

| Housing Protection | Board-level design (no IP-rated enclosure) | Ideal for OEM integration into custom housings |

| Size & Weight | 36.0 × 36.0 × 26.3 mm, approx. 13 g | Lightweight, compact form factor for embedded and multi-camera systems |

Ideal Applications

1. Near-Infrared Food Sorting and Contaminant Identification

In automated food processing, near-infrared imaging is widely used to separate edible products from unwanted materials that appear similar under visible light. With an NIR-sensitive monochrome sensor, this camera can distinguish organic food from plastics, stones, or packaging residues based on their infrared response. The 5 MP resolution allows detection of small contaminants, while high frame rates support continuous conveyor operation. Adjustable exposure settings help maintain consistent image quality under varying illumination. Hardware triggering ensures accurate timing with belt encoders and lighting, improving detection reliability and reducing false rejections in high-throughput food inspection systems.

2. Semiconductor and PCB Layer Inspection

Near-infrared imaging is commonly applied in semiconductor and PCB manufacturing to reveal features beneath surface layers. This camera enables inspection of silicon wafers, bonding interfaces, and multilayer boards by capturing contrast invisible to standard cameras. Fine pixel resolution and high grayscale depth allow subtle defects such as cracks, voids, or alignment issues to be detected. Controlled rolling shutter operation supports stable imaging on precision motion stages. Trigger inputs and GPIO lines enable tight synchronization with inspection equipment, helping manufacturers improve yield and detect defects earlier in advanced electronics production.

3. Code Reading on Dark or Reflective Surfaces

Laser markings, inkjet codes, and etched symbols on dark plastics or metals often suffer from low contrast under visible illumination. Near-infrared imaging enhances the contrast between markings and background surfaces, improving readability. This camera captures high-resolution grayscale images suitable for OCR and verification algorithms. Region-of-interest control reduces unnecessary data processing, while stable frame rates support inline inspection. These capabilities make the camera effective for traceability systems in automotive, electronics, and industrial manufacturing where reliable code verification is essential for quality control.

4. Agricultural Produce Quality Evaluation

In agricultural inspection, near-infrared imaging is used to assess internal characteristics such as ripeness, bruising, or moisture levels without damaging the produce. This camera enables consistent NIR image capture for fruits, vegetables, and grains, supporting automated grading and sorting. Long exposure capability allows operation with low-intensity lighting, while USB3 data transfer supports real-time analysis. Its compact size and low power requirements simplify integration into mobile or space-limited inspection machines, helping modern agriculture systems improve quality consistency and reduce waste.

5. Scientific and Material Analysis Imaging

Research and development environments frequently rely on near-infrared imaging to study materials, chemical processes, and biological samples that respond outside the visible spectrum. This camera provides stable grayscale output with sufficient bit depth to capture subtle intensity changes needed for quantitative analysis. Flexible exposure control supports repeatable experiments, while hardware triggering enables synchronization with lasers, motion stages, or other instruments. The board-level design allows seamless integration into custom optical setups, making it suitable for laboratory research, prototyping, and experimental validation involving NIR wavelengths.

Related Products & Accessories

IDS Accessories

-

S-Mount (M12) NIR Lenses – Optimized for 1/2.5″ sensors and near-infrared imaging

-

USB3 Type-C Industrial Cables – Stable high-speed data transfer for embedded and industrial systems

-

Trigger & I/O Cables (8-Pin) – Supports hardware triggering, flash control, and GPIO synchronization

-

NIR LED Illumination Modules – Near-infrared lighting for inspection, code reading, and material analysis