1. High-Speed Conveyor Inspection in Automated Production

In modern manufacturing lines, products often move continuously at high speed, making image distortion a major challenge. A global shutter camera such as the U3-3072ACP Rev.1.2 captures the entire image at once, preserving true object geometry even during rapid motion. High frame rates allow multiple inspections per item, increasing detection confidence for defects such as misalignment, surface damage, or missing components. Hardware triggering ensures images are captured at precise positions on the conveyor, while region-of-interest settings reduce processing load. This approach improves inspection accuracy and supports stable quality control in high-throughput production environments.

2. Vision Guidance for Robotic Pick-and-Place Systems

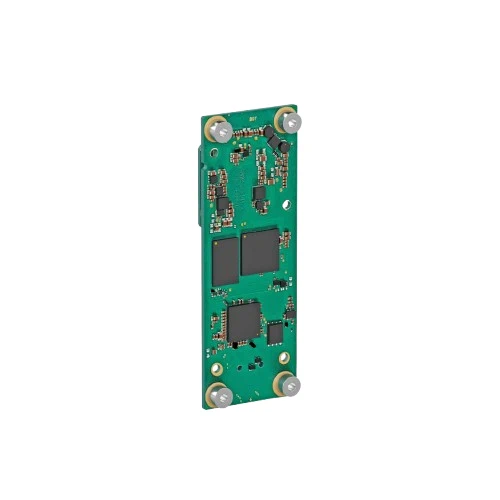

Robotic pick-and-place operations rely on accurate visual feedback while both the robot and objects may be moving. Global shutter imaging eliminates motion blur caused by arm movement, enabling reliable object localization and orientation detection. High frame rates provide frequent visual updates, allowing robots to adjust trajectories in real time. The compact board-level design supports installation directly on robotic arms or within confined tool heads. Combined with deterministic triggering and low-latency data transfer, this setup enhances precision, reduces cycle time, and improves reliability in electronics assembly, logistics automation, and small-parts handling.

3. Precision Measurement and Automated Metrology

Measurement systems require geometrically accurate images to ensure reliable dimensional analysis. Global shutter technology ensures that edges and features are captured without distortion, which is critical for gauging, alignment checks, and tolerance verification. Fine pixel resolution supports detailed feature extraction, while controlled exposure settings maintain consistent image quality under stable lighting. Region-of-interest processing allows measurement algorithms to focus on critical areas only, improving processing efficiency. These capabilities are commonly used in automated metrology stations for quality assurance in mechanical, electronic, and precision-manufactured components.

4. Traffic Monitoring and Intelligent Transport Systems

Vehicles moving at speed present significant imaging challenges for monitoring and analysis systems. A global shutter sensor captures sharp images of vehicles without skew, enabling accurate detection of contours, identifiers, and motion events. High frame rates improve tracking consistency and support reliable speed or flow analysis. Precise exposure control helps maintain clarity across changing lighting conditions, such as daylight, dusk, or artificial illumination. These characteristics make compact industrial cameras well suited for embedded traffic monitoring units and intelligent transportation systems operating continuously in real-world environments.

5. Scientific Imaging and Laboratory Automation

Laboratory and research systems often involve fast, repeatable motion, including sample transport, rotating stages, or fluid flow. Global shutter imaging prevents motion-induced artifacts, preserving data integrity for analysis and documentation. Long-exposure capability supports low-light experiments, while precise triggering enables synchronization with experimental events or external instruments. The small, low-power board-level format integrates easily into custom analytical equipment. These features are valuable in laboratory automation and scientific imaging applications where consistent timing, repeatability, and accurate motion capture are essential for dependable results.