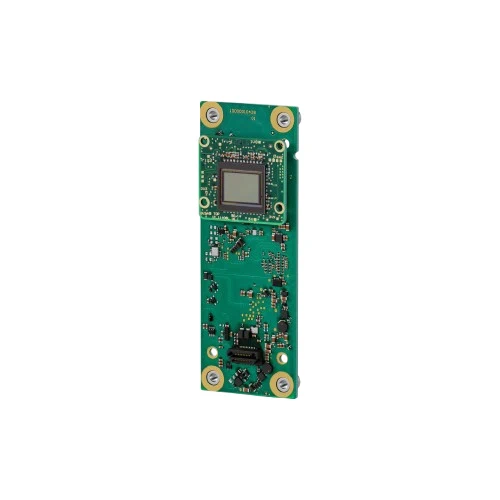

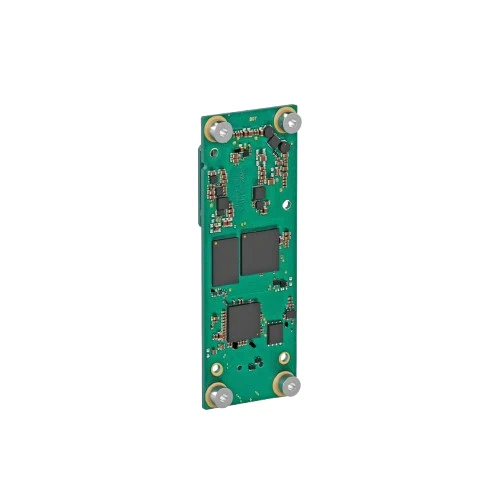

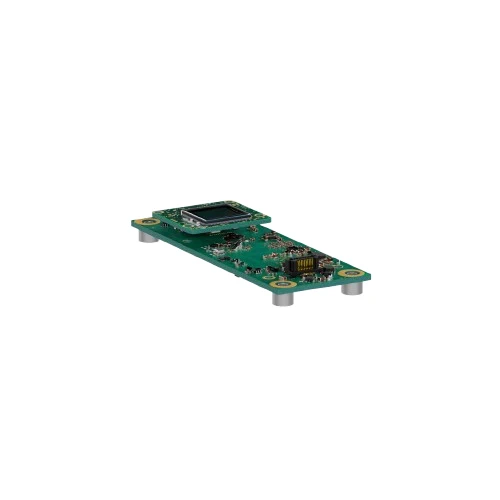

The Applications for the U3-3042ACP Rev.1.2 Global Shutter Camera

1. High-Speed Pick-and-Place Inspection in Electronics Assembly

In modern electronics manufacturing, components move rapidly and must be inspected without interrupting production flow. The U3-3042ACP Rev.1.2 captures sharp, undistorted images of fast-moving parts thanks to its global shutter sensor. High frame rates allow multiple images to be taken during a single motion cycle, improving defect detection reliability. Precise hardware triggering ensures images are captured at consistent positions on the conveyor. Its compact board-level design fits easily into restricted spaces above assembly lines, enabling accurate inspection without mechanical redesign or reduced throughput.

2. Vision-Based Robotic Guidance and Alignment

Robotic systems require consistent visual feedback to position tools and components accurately. This camera supports robotic guidance by delivering clear images during continuous motion, avoiding the geometric distortion that can mislead vision algorithms. Region-of-interest control reduces processing load, improving system response time. High-speed data transfer enables real-time feedback for closed-loop control. Its lightweight PCB construction allows direct mounting on robotic arms or end effectors, minimizing added mass and maintaining robot speed, precision, and long-term operational stability.

3. Motion Analysis in Industrial Test and Validation Systems

Industrial test benches often involve observing fast mechanical movements such as actuators, gears, or rotating shafts. The U3-3042ACP Rev.1.2 enables engineers to freeze rapid motion without blur, making it easier to analyze timing, displacement, and repeatability. Adjustable exposure and high frame rates support detailed analysis of short-lived events. Long exposure capability also assists in low-light test environments. Combined with synchronized triggering, the camera provides repeatable, reliable image data for performance validation and failure investigation.

4. Inline Inspection for Packaging and Printing Lines

Packaging and printing operations demand accurate inspection at high conveyor speeds. This camera delivers stable imaging of moving labels, codes, and printed patterns without skew or motion artifacts. Global shutter capture ensures consistent image geometry, while flexible image processing options allow optimization for speed or sensitivity. The slim form factor enables integration into compact inspection stations, supporting modular quality control systems. These capabilities help manufacturers detect defects early, reduce waste, and maintain consistent product presentation at scale.

5. Scientific and Laboratory Imaging of Fast Events

Research and laboratory applications often require precise observation of rapid physical or optical phenomena. The U3-3042ACP Rev.1.2 provides accurate temporal capture through fine exposure control and external synchronization. Its global shutter sensor prevents readout-related artifacts that could affect measurement accuracy. High frame rates support time-resolved studies, while the board-level design allows easy integration into custom experimental setups. This combination makes the camera suitable for repeatable scientific imaging where timing accuracy and data integrity are essential.