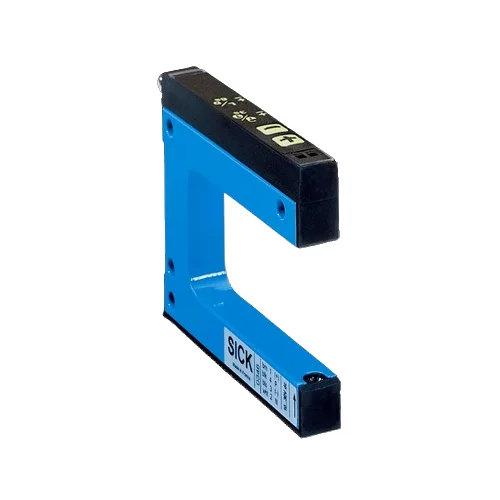

SICK WF120-40B410 Fork Sensor – Reliable Infrared Detection for High-Speed Labeling

The SICK WF120-40B410 Fork Sensor is a high-precision optical sensor designed to detect labels and thin materials with exceptional accuracy. With a 120 mm fork width and infrared LED detection, it identifies objects as small as 0.2 mm, making it ideal for labeling and packaging lines that demand fast and reliable performance. The compact aluminum housing offers IP65 protection, while the adjustable sensitivity controls simplify calibration during setup. Its 10 kHz switching frequency and rapid ≤100 µs response time ensure smooth performance in fast-moving automation systems where precision timing is critical.

Engineered for continuous industrial use, the WF120-40B410 provides dependable performance across varied applications such as print-and-apply systems, bottling lines, and carton labeling. The dual PNP/NPN output flexibility makes integration easy with existing controllers. Operators can fine-tune detection using simple push-button adjustments, reducing setup time and eliminating alignment errors. The sturdy aluminum frame and high immunity to ambient light maintain stability in demanding environments. By ensuring consistent detection of transparent or reflective labels, this sensor helps minimize production errors, lowers downtime, and improves overall efficiency in automated manufacturing processes.

Why SICK WF120-40B410?

Because precision and speed matter. The SICK WF120-40B410 combines infrared accuracy, ultra-fast 10 kHz response, and easy sensitivity adjustment to detect even the thinnest labels or materials. Built in a rugged aluminum housing with IP65 protection, it delivers stable performance that production engineers can trust shift after shift.

What Problem Does It Solve?

The WF120-40B410 eliminates labeling and packaging errors caused by inconsistent or missed detections. It ensures flawless label placement, even with transparent or reflective materials, preventing misprints and downtime. Ideal for high-speed production lines where every millisecond counts, it turns detection challenges into seamless automation efficiency.

Key Features & Specifications – SICK WF120-40B410: 6028435

| Feature | Details | Benefit |

|---|---|---|

| Detection Principle | Optical, infrared LED | Provides accurate detection even on transparent or reflective labels. |

| Fork Width / Depth | 120 mm / 42 mm | Wide detection area for various label and packaging sizes. |

| Minimum Detectable Object | 0.2 mm | Detects very thin materials and ensures precise trigger response. |

| Response Time | ≤ 100 µs | Ideal for high-speed labeling and packaging systems. |

| Switching Frequency | 10 kHz | Ensures stable, rapid detection with minimal delay. |

| Output Type | Selectable PNP/NPN | Flexible integration with diverse automation controllers. |

| Adjustment Control | Plus/Minus buttons | Simple setup with direct sensitivity and light/dark switching. |

| Supply Voltage | 10–30 V DC | Broad voltage range for compatibility with industrial systems. |

| Current Consumption | 40 mA typical | Energy-efficient for continuous operation. |

| Enclosure Rating | IP65 | Resistant to dust and moisture, ensuring reliable use in harsh conditions. |

| Housing Material | Aluminum | Robust construction for durability and long lifespan. |

| Operating Temperature | –20 °C to +60 °C | Stable performance across demanding environments. |

| Connection Type | M8, 4-pin male connector | Quick and secure electrical connection for easy installation. |

| Certifications | CE, UKCA, cULus, China RoHS | Complies with major international safety and quality standards. |

| Typical Applications | Label detection, print-and-apply, packaging lines | Ensures smooth, error-free detection for automated labeling. |

Download SICK WF120-40B410 (6028435) Datasheet

Commercial Information – SICK WF120-40B410: 6028435

| Commercial Data | Details |

|---|---|

| EAN Number | 4047084112294 |

| Weight | 0.101 g |

| Country of Origin | France |

The Applications of SICK WF120-40B410 Fork Sensor

1. Precision Labeling in Beverage Production Lines

In automated labeling systems for bottles and cans, accuracy and timing are critical. The WF120-40B410’s infrared optical detection identifies even the thinnest or transparent labels moving at high speed. With its fast 10 kHz switching frequency and 0.2 mm sensitivity, it ensures every label is placed correctly, reducing waste and downtime. Its durable aluminum body withstands vibration and moisture common in beverage facilities, guaranteeing consistent performance throughout continuous shifts.

2. Edge and Cutout Detection in Flexible Packaging Films

When working with continuous rolls of packaging film, identifying perforations, edges, or gaps can be difficult. The WF120-40B410 precisely senses these transitions, even on glossy or semi-transparent materials. Its quick response time allows instant feedback for cutting or sealing operations. By detecting imperfections early, it prevents defective packaging from reaching final assembly, improving product consistency and reducing rework or scrap.

3. Transparent Bottle and Tube Level Verification

In cosmetic and pharmaceutical filling stations, the need to confirm the presence of liquid in clear containers is vital. The WF120-40B410 detects the optical difference between filled and empty containers without any physical contact. Its infrared beam remains stable despite reflections from curved surfaces, ensuring that underfilled or missing bottles are identified before capping. This enhances quality control and supports fast, automated inspection cycles.

4. Splice and Web Monitoring in Label Roll Changeovers

During high-speed label roll replacement, splice points must be detected to maintain alignment and prevent labeling errors. The WF120-40B410 instantly recognizes the small thickness variation when two label webs join. Its high switching frequency provides accurate timing, allowing machinery to adjust or pause automatically. This smooth changeover process keeps production continuous, prevents label misfeeds, and minimizes downtime during roll transitions.

Related Products & Accessories – SICK WF120-40B410: 6028435

| Category | Model Name | Part Number | Benefits / Description |

|---|---|---|---|

| Accessory – Connector | STE-0804-G | 6037323 | 4-pin M8 male connector, straight type, unshielded. Ideal for quick connection to control units. |

| Accessory – Sensor Cable | YF8U14-050VA3XLEAX | 2095889 | 5 m PVC cable, 4-wire, M8 female connector with flying leads. Suitable for general automation zones. |

Contact Us

For expert guidance before placing your order.

Warranty – 1-year warranty for your peace of mind.

Global Shipping – We ship worldwide with secure packaging and reliable delivery.

Technical Support – Contact us for professional after-sales technical assistance.