The Applications

1. Precision Label Gap Detection in High-Speed Labeling Machines

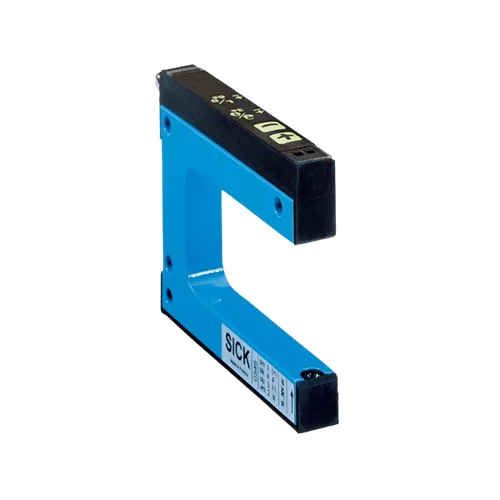

In automatic labeling systems, accurate detection of the gap between labels is critical for correct placement on products moving at high speed. The SICK WF5-60B410 is well suited for this task because its fork design maintains a fixed optical path, eliminating alignment drift caused by vibration or mechanical wear. The infrared detection principle allows the sensor to reliably differentiate between the label backing material and the gap, even when labels are transparent or semi-transparent. Fast switching and short response time help prevent missed labels or double application. This results in consistent label positioning, reduced waste, and stable operation during speed changes or frequent product changeovers.

2. Registration Mark Detection on Flexible Packaging Film

Flexible packaging machines rely on precise detection of printed registration marks to control sealing, cutting, and print alignment. The SICK WF5-60B410 can monitor the film directly within its fork, providing stable detection even when the web vibrates or tension fluctuates. Its high immunity to ambient light and fast response support accurate recognition of marks on glossy, matte, or lightly patterned films. Sensitivity adjustment allows operators to adapt quickly to different print contrasts and film thicknesses. By maintaining consistent registration control, the sensor helps reduce off-center seals, misaligned graphics, and startup scrap, improving overall packaging quality and throughput.

3. Double-Sheet and Overlap Detection in Paper and Carton Feeding

In carton feeders and paper handling equipment, overlapping sheets can cause jams, misfeeds, or downstream process failures. The SICK WF5-60B410 is commonly used to monitor the material path where space is limited and mechanical guides are close together. Its narrow fork opening enables precise detection of abnormal material presence, helping the control system identify double feeds or overlaps early. Fast detection allows the machine to stop or reject material before damage occurs. This reduces downtime, protects tooling, and improves operational efficiency, especially in high-speed printing, converting, and packaging lines handling thin paper or folded inserts.

4. Small-Part Presence and Edge Detection in Automated Assembly

Automated assembly systems often require confirmation that a small component, tab, or punched feature is present before the next process step begins. The SICK WF5-60B410 supports this requirement by providing a defined sensing window that minimizes false triggers from background reflections. Its ability to detect very small objects and respond quickly makes it suitable for checking metal stamps, plastic parts, or fine edges during assembly. Reliable detection helps prevent incomplete assemblies, tooling collisions, and quality defects. As a result, manufacturers can achieve higher process reliability, improved yield, and safer operation in compact, high-speed assembly cells.

Related Products & Accessories – SICK WF Series

| Category | Model Name | Part Number | Benefits |

|---|---|---|---|

| Connector / Terminal | STE-0804-G | 6037323 | Enables fast, reliable field wiring with screw terminals; compact solution for WF series fork sensors |

| Sensor / Actuator Cable | YF8U14-050VA3XLEAX | 2095889 | Pre-assembled cable simplifies installation and servicing; suitable for standard industrial environments |