GV100 Hyperspectral Gold‑Plating Verifier

What GV100

AXMATIC’s GV100 is a tabletop hyperspectral imaging (HSI) station that verifies 24K gold coverage on flex circuits, connectors, and package substrates. It detects the spectral signature of gold per pixel, counts gold only within metal regions (Cu/Ni/Au), and automatically assigns A/B/C/D/F grades from your thresholds. Use GV100 for coverage & uniformity; pair with XRF only when you need thickness/alloy confirmation.

Use GV100 for coverage & uniformity; reserve XRF for thickness/alloy checks. Outcomes: fewer escapes, fewer false rejects, faster MRB, and clear overlay evidence.

Why GV100 Beats Human Inspection & AVI/AOI

The problem in detail

- Human limits: fatigue & vigilance drift during long microscope sessions; poor absolute color memory (without a color card under identical lighting); glare and white‑balance changes that make pads look richer/duller with no plating change.

- AVI/AOI limits: pipelines often reduce to grayscale intensity and edge features—insensitive to hue/spectrum—and are easily fooled by specular highlights or cosmetic stains.

The GV100 solution

- Spectral classification (not color) recognizes gold’s fingerprint.

- Metal‑only masking counts coverage only within Cu/Ni/Au pads.

- Locked recipes (illumination, focus/Z, masks, thresholds).

- Evidence overlays show exactly why a unit passed/failed.

Side‑by‑Side Comparison

| Criteria | Human / AVI / AOI | GV100 Hyperspectral |

|---|---|---|

| Decision basis | Color/contrast; subjective | Spectral Au signature + metal mask; numeric thresholds |

| Sensitivity to glare | High | Low — robust to shine/discoloration |

| Consistency | Operator/recipe drift | Locked recipes; stable grading across lots |

| Coverage vs spot | Sampled ROIs only | Full‑field, per‑pixel coverage grading |

| False calls | Higher on tricky lots | Reduced; overlay shows exactly why |

| Traceability | Varies by operator | CSV/JSON + image overlays for SPC & audits |

Key advantage: Objective decisions with visible evidence overlays that speed MRB and close supplier quality loops.

How It Works (in 4 steps)

Step 2: Classify each pixel inside the mask as gold/non‑gold by spectral signature.

Step 3: Grade coverage automatically (A/B/C/D/F) from your pass/fail thresholds.

![]()

Step 4: Export image overlays + CSV/JSON for SPC, audits, and traceability.

Key Features

- Per‑pixel spectral gold classifier (objective; robust to glare)

- Metal‑only masking (counts only within Cu/Ni/Au regions)

- Automatic A/B/C/D/F grading (user thresholds)

- Full‑field coverage view (see local islands/voids spot checks miss)

- Evidence overlays (gold‑positive pixels for fast MRB)

- CSV/JSON export (SPC, traceability, audits)

- Compact tabletop station (Windows® 10; USB 3.x; Z‑adjust)

Detailed specifications, FOV options, and footprint can be finalized for your chosen optics/mechanics.

Typical Deployment

- Incoming Inspection: Rapid screening; escalate only borderlines to XRF.

- Line‑side QC: Short cycle checks with locked recipes; SPC trend monitoring.

- Supplier Quality: Use overlays + CSV/JSON to close the loop with vendors.

Application

1) Flex PCB ACF bond pad readiness

Quantify coverage across every fine‑pitch pad before bonding. Catch thin islands and plating voids that pass a quick visual glance. Link grades to electrical yields and cut debug time during ramp.

2) Connector contact fingers

Selective‑gold contacts often look perfect under white light yet fail early. Full‑field grading exposes local under‑plating, stabilizing insertion loss and tightening maintenance windows.

3) Package substrates & interposers

Identify partial gold exposure on RDL pads and seal rings that creates marginal assembly interfaces. Confirm thickness on select ROIs by XRF to accelerate MRB.

4) ENIG/ENEPIG process monitoring

Grade distributions shift before line‑down defects. Trend %A and Cpk across panels/lots; schedule predictive bath maintenance.

5) Wire‑bond pad surface readiness

Spectral decisions cut through residues/roughness that confuse AOI. Correlate with pull/shear during NPI; lock thresholds for stable production.

6) Medical & instrumentation micro‑contacts

Verify uniform gold on micro‑contacts for biocompatibility and low‑noise signals. Overlays make supplier conversations fast and objective.

7) RF/microwave contact interfaces

Flag local voids/thin Au islands on RF lands and spring fingers to minimize resistance drift and passive intermodulation.

8) Aerospace/avionics harness terminations

Ensure uniform Au on crimp tabs and springs for corrosion resistance and vibration‑proof connections.

FAQs

Does GV100 measure thickness?

GV100 verifies coverage/uniformity. Use XRF for thickness/composition on select ROIs.

How fast is it?

Seconds per field of view in typical lab use.

What training is needed?

Short onboarding; recipes lock settings so results are consistent across shifts.

Can we integrate with our SPC/MES?

Yes — CSV/JSON exports are ready to ingest.

Contact Us for More Information

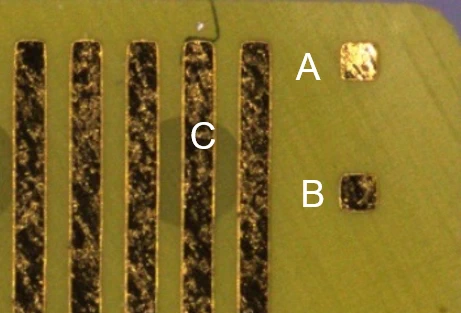

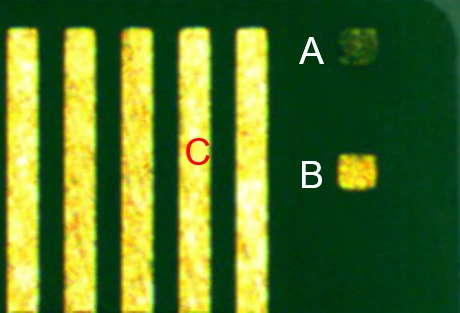

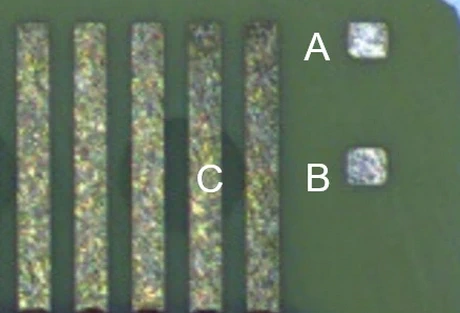

Validation Story: Three Pads, Three Calls (A, B, C)

Based test summary (XRF = ground truth).

Table recap

A = NG by XRF/HSI

B/C = OK by XRF/HSI.

Operators and industrial camera (AVI) mis‑judged.

| Area | XRF (Truth) | Operator Visual | AVI (Industrial Cam) | GV100 HSI | What happened & why |

| A | NG | OK | NG | NG | Pad looked “gold” under white light (specular shine). Operator trusted color memory; AVI flagged by intensity threshold. GV100 read the spectral fingerprint and correctly called under‑plating (example: ~0.014 µm from XRF). |

| B | OK | NG | NG | OK | Cosmetic darkening/illumination made the pad look dull. Human and AVI (grayscale) treated it as NG. GV100 saw true Au spectrum across the pad → Pass. |

| C | OK | NG | NG | OK | Similar to B: visual dullness and highlights fooled brightness‑based judgement. GV100’s spectral decision held; XRF confirmed OK thickness. |

What each method is really using

- Human: brightness/contrast + imperfect color memory; highly sensitive to fatigue and lighting drift.

- AVI: grayscale thresholds/edges; sometimes RGB, but still broad‑band and easily fooled by glare or exposure. Not a material test.

- GV100 HSI: multi‑band spectral signature of Au within a metal‑only mask; locked thresholds; evidence overlay.

Failure patterns (why mis‑judgment happens)

- Human: long sessions → vigilance drop; color‑tone recall is poor without a color card; microscope brightness/angle changes the perceived tone.

- AVI: converts to grayscale or reduces to RGB → insensitive to hue; specular highlights saturate pixels; cosmetic stains shift histograms.

- GV100: will disagree only if the recipe/illumination is out of spec or the gold library is outdated → fixed by recipe control and periodic validation.

Accuracy, Validation & Repeatability

- Site‑specific correlation: Lock coverage thresholds by correlating GV100 grades with XRF on representative ROIs.

- Recipe control: Illumination, focus/Z, masks, and classifiers are locked to remove operator drift.

- SPC‑first: Track coverage %, grade distribution, and trend drift before escapes occur.

- Evidence overlays: Show gold‑positive pixels, so QA can see why a unit passed/failed.

GV100 measures coverage/uniformity. Use XRF for thickness and composition.

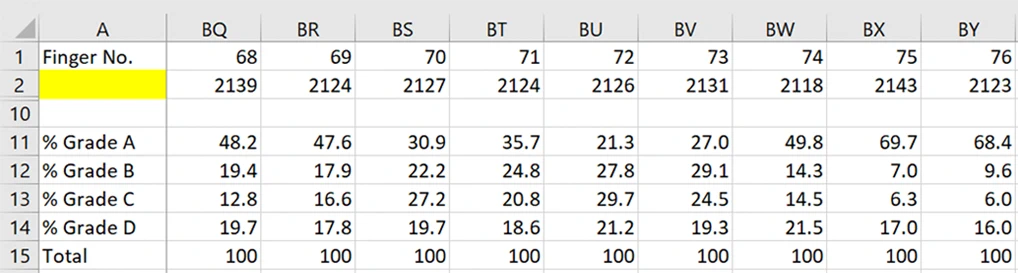

Independent XRF Correlation (Third‑Party)

Purpose: show thickness truth alongside GV100’s coverage calls so customers trust both speed and accuracy.

Test setup: Au‑NiP‑Cu stack; 12 sites measured by Bowman XRF (representative coupon).

Results (thickness):

- Gold (Au): min 0.019 µm, max 0.055 µm, mean 0.040 µm, stdev 0.0127 µm (~31.96% rel.)

- Nickel‑P (NiP): min 0.706 µm, max 2.130 µm, mean 1.408 µm, stdev 0.404 µm (~28.70% rel.)

What this proves:

- GV100’s coverage grades align with the direction of thickness variation confirmed by XRF: thin areas that “look gold” visually still grade NG on GV100 and read low Au on XRF; darker‑looking but acceptable areas grade OK and read in‑spec thickness.

- Use GV100 to screen full fields in seconds; reserve XRF for spot confirmation and periodic correlation.

- Publish this correlation on the intro page to establish trust: “GV100 = coverage/uniformity; XRF = thickness/chemistry.”

SPC Purpose: log GV100 coverage %, grade distribution (%A/%B), and periodic XRF Au µm for the same product family. Trend drift → schedule plating bath maintenance before escapes.