Ideal Applications

1. High-Speed Conveyor Inspection for Small Mechanical Parts

In automated production lines, small components often move at high speed, making visual inspection difficult with rolling shutter cameras. A global shutter sensor captures each object at a single moment in time, preventing image distortion and preserving edge accuracy. The 1920 × 1200 resolution provides sufficient detail to identify surface defects, dimensional errors, or missing features without slowing throughput. Hardware triggering allows images to be taken at precise positions on the conveyor, while region-of-interest and binning functions help manage data bandwidth. This combination enables stable, real-time inspection in compact inline systems where space and processing efficiency are critical.

2. Vision-Guided Robotics for Pick-and-Place Automation

Robotic handling systems require accurate visual feedback to locate and grasp moving objects reliably. By using a global shutter sensor, image geometry remains stable even when objects or robotic arms are in motion. High frame rates support fast feedback loops, allowing robots to react quickly to changing positions. The compact camera design allows mounting on robot arms or fixed frames, while USB3 communication ensures low-latency image transfer. Trigger and I/O signals support synchronization with robot controllers and lighting, improving placement accuracy and reducing cycle time in automated assembly environments.

3. Optical Measurement and Dimensional Verification

Dimensional inspection systems depend on consistent geometry and repeatable image capture to achieve accurate measurements. Global shutter imaging avoids skew and deformation when parts are not completely stationary, improving the reliability of edge detection and measurement algorithms. The sensor’s pixel size and optical format support detailed analysis of small features, while adjustable exposure and gain help maintain contrast across different materials. High frame rates allow multiple measurements per second, enabling inline verification without interrupting production flow, which is essential for modern quality assurance processes.

4. Traffic and Mobility Monitoring in Controlled Facilities

In environments such as parking structures or industrial transport lanes, vehicles may move quickly through narrow spaces. Global shutter capture ensures that moving wheels, identifiers, or structural details remain sharp and undistorted. High frame rates reduce the risk of missed events, while long exposure options support operation in challenging lighting conditions. The camera’s small form factor enables flexible installation at overhead or side-mounted positions. Event-based triggering allows images to be captured only when motion occurs, improving system efficiency and data management in monitoring applications.

5. Scientific and Laboratory Motion Analysis

Research applications involving mechanical motion, material testing, or dynamic experiments require precise timing and accurate geometry. A global shutter sensor exposes all pixels simultaneously, ensuring that fast-moving subjects retain their true shape. High frame rates allow the capture of transient phenomena that occur over very short time intervals. Flexible exposure control supports a wide range of illumination setups commonly used in laboratories. With simple USB integration and compact size, the camera fits well into modular test rigs and benchtop systems where accuracy, repeatability, and ease of setup are essential.

Related Products & Accessories

IDS Accessories

-

C-Mount / CS-Mount Lenses – Optimized for 1/2.6″ sensors

-

USB3 Type-C Industrial Cables – Stable high-speed data transfer for USB3 Vision systems

-

I/O Trigger & Flash Cables – Synchronization with external sensors and lighting

-

Machine Vision LED Lighting – Strobe and continuous illumination support

IDS Imaging Cameras

-

U3-3271LE Series – 3.2 MP USB3 cameras for higher-resolution inspection

-

U3-3684XLE Series – High-speed global shutter USB3 cameras

Contact US

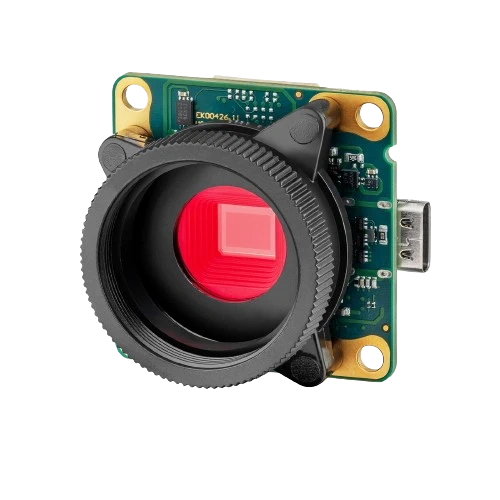

As an authorized distributor of IDS products, we offer certified expertise and technical support to ensure you get the most out of your U3-3684XLE Rev.1.1 camera. We stand by the quality of our products and provide comprehensive warranty services. Our team can also assist with special services like custom integration and creating pre-configured kits tailored to your specific needs.

- Contact Us: Get in touch with our technical support team for detailed inquiries about the U3-3684XLE Rev.1.1 ‘s features and integration.

- Request a Quote: Planning a large-scale project? Contact us for a bulk quote or OEM pricing.

- Download Software: Access the necessary software, APIs, and manuals to get started with your IDS camera.

- Email: sales@inosaki.com