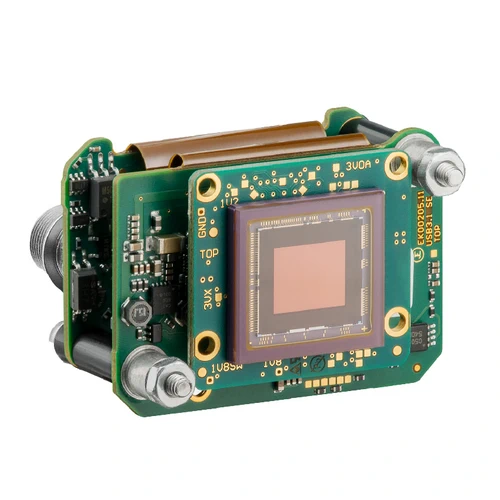

IDS U3-3272SE USB3 Vision Camera with Sony IMX265 Global Shutter

Product Description

The IDS U3-3272SE is a compact 3.2 MP USB3 industrial camera developed for reliable imaging in high-speed and embedded vision systems. Based on the Sony IMX265 global shutter sensor, it delivers a resolution of 2064 × 1544 pixels, ensuring distortion-free capture of fast-moving objects in inspection and automation tasks. Available in monochrome and color variants, the camera supports precise image acquisition while its lightweight PCB design and USB Type-C interface simplify integration into space-constrained OEM platforms.

With a 1/1.8″ optical format and 3.45 μm pixel size, the U3-3272SE provides stable image quality across varying lighting conditions. Frame rates up to 58 fps, combined with hardware triggering, long exposure capability, and on-board image preprocessing, help reduce system latency and host workload. These features make it suitable for motion analysis, synchronized inspection, and embedded machine vision applications requiring consistent and predictable performance.

Technical Capabilities

-

3.2 MP Sony IMX265 CMOS Sensor – 2064 × 1544 resolution with global shutter for distortion-free imaging

-

Up to 58 fps @ Full Resolution – High-speed performance for dynamic inspection and motion analysis

-

USB3 Vision Interface (USB Type-C) – High-bandwidth, low-latency data transfer for real-time processing

-

Global Shutter Architecture – Accurate capture of fast-moving objects without motion artifacts

-

Advanced Image Control – Programmable exposure, gain, triggering, long exposure, and ROI

-

Industrial SDK & GenICam Support – Seamless system integration via IDS Imaging Development Systems software ecosystem

Specifications

- Color: U3-3272SE-C (AB02866)

- Mono: U3-3272SE-M (AB02867)

| Feature | Details | Application Advantage |

|---|---|---|

| Sensor Brand & Model | Sony IMX265 (Color: IMX265LQR / Mono: IMX265LLR) | Proven industrial-grade sensor delivering stable and repeatable image quality |

| Sensor Type | CMOS, Global Shutter | Eliminates motion blur for accurate capture of fast-moving objects |

| Interface | USB3 Vision (USB Type-C) | Ensures broad compatibility and simple plug-and-play integration |

| Interface Speed | USB 3.0 High-Speed | Supports high data throughput with low latency for real-time processing |

| Resolution (H × V) | 2064 × 1544 pixels (3.2 MP) | Balanced resolution for inspection, measurement, and embedded vision |

| Optical Area (H × V) | 7.093 mm × 5.320 mm | Efficient sensor coverage for common industrial lenses |

| Optical Format | 1/1.8″ (Diagonal 8.87 mm) | Wide compatibility with C-mount and industrial optics |

| Pixel Size | 3.45 µm × 3.45 µm | High sensitivity and stable performance under varied lighting |

| Lens Mount | No mount (PCB camera) | Ideal for OEM and custom embedded system designs |

| Image Memory | 128 MB onboard buffer | Prevents frame loss during burst capture or triggering |

| Frame Rate @ Max. Resolution | Up to 58 fps | Enables high-speed inspection and motion analysis |

| Shutter | Global Shutter | Accurate geometry and timing in dynamic scenes |

| Exposure Time | 0.025 ms to 2000 ms (up to 90 s long exposure) | Supports both high-speed capture and low-light imaging |

| Trigger & Flash I/O | Hardware trigger input, flash output, GPIO via 8-pin Hirose | Precise synchronization with external equipment |

| Power Supply | USB-powered | Simplifies system wiring and reduces integration cost |

| Software Tools | IDS peak SDK, GenICam compliant | Fast development, configuration, and long-term software support |

| Environmental Tolerance | Operating: 0 °C to +55 °C, non-condensing | Reliable operation in industrial environments |

| Housing Protection | Open PCB design | Optimized for integration into protected enclosures |

| Size & Weight | 29.5 × 40 × 25 mm, approx. 20 g | Compact and lightweight for space-constrained systems |

- Download IDS U3-3272SE-C Datasheet

- Download IDS U3-3272SE-M Datasheet

- Download IDS U3-3272SE Technical Drawing

Ideal Applications

1. High-Speed Conveyor Belt Inspection

In automated production environments, products often move continuously at high speed, making it difficult to capture sharp images using standard cameras. The U3-3272SE overcomes this by using a global shutter sensor that exposes all pixels at the same instant, preserving object geometry during motion. Its ability to operate at up to 58 frames per second allows frequent image sampling, while hardware triggering ensures images are captured at repeatable positions on the line. Region-of-interest and data reduction functions help focus processing power on critical features, enabling dependable defect detection and dimensional checks in electronics, packaging, and mechanical production systems.

2. Precision Robotic Pick-and-Place Guidance

Robotic handling systems require consistent visual feedback to identify part position and orientation accurately. The U3-3272SE supports this by delivering distortion-free images even when the robot arm is in motion. The 3.2 MP resolution provides sufficient spatial detail for object recognition tasks, while fast USB3 data transfer keeps control loops responsive. Trigger-controlled exposure aligns image capture with robot movement, improving repeatability during high-speed cycles. These characteristics help reduce placement errors, increase throughput, and support stable operation in automated assembly, sorting, and logistics applications.

3. Motion Analysis in Industrial Testing

Evaluating mechanical motion often involves observing fast or repetitive movement under controlled conditions. The global shutter sensor in the U3-3272SE allows engineers to capture crisp images of rotating parts, vibrating assemblies, or moving actuators without geometric distortion. Short exposure times freeze rapid motion, while extended exposure options support testing in low-light environments. The camera’s compact PCB design makes it easy to integrate into custom test setups. This enables detailed analysis of movement behavior, fault detection, and performance validation during product development and industrial testing.

4. Automated Optical Inspection for PCBs

Inspection of printed circuit boards requires stable imaging to reveal fine structural details such as solder joints and component alignment. The U3-3272SE provides consistent image capture as boards move between processing stages, avoiding skew or blur. Its higher bit depth supports better contrast when identifying subtle surface variations. Hardware triggering ensures synchronization with transport mechanisms, delivering repeatable inspection conditions. By combining precise timing with flexible image control, the camera supports reliable quality assessment in both inline and standalone PCB inspection systems.

5. Embedded Vision in Compact Industrial Devices

Many industrial products integrate vision capabilities within limited space and power budgets. The U3-3272SE is well suited for these designs due to its lightweight PCB form factor and USB-powered operation. The global shutter sensor maintains image stability despite vibration or operator movement, while adjustable image formats and preprocessing features help balance image quality with processing requirements. These attributes allow developers to build compact, vision-enabled devices that deliver dependable performance in smart sensing, portable inspection, and embedded automation applications.

Related Products & Accessories

IDS Accessories

-

C-Mount Lenses – Optimized for 1/1.8″ sensors

-

USB3 Vision Cables (USB Type-C) – Stable high-speed data transfer for USB3 cameras

-

8-Pin Hirose I/O Cables – Supports hardware trigger, GPIO, and flash control

-

LED Machine Vision Lighting – Trigger-synchronized illumination for consistent image capture

IDS Imaging Cameras

-

U3-3271LE Series – 3.2 MP Sony IMX265 in compact USB3 housing